The Rebirth of Luna

Luna’s been rebirthing. You’d think she would have learned!

Luna’s about 7 years old. For an oven built as a prototype, that’s getting on. She’s had a robust, quite eventful life so far. She’s lived in four locations, as well as a short stint living ‘on the road’, as the centrepiece to my first travelling bakery and classroom. She was designed to be a mobile, high volume wood fired oven. She was meant to be light, heat up quickly, and be able to bake 300 or more perfect loaves of bread in the space of a market - which would be around eight hours.

For this task, she was a complete failure. The entire mobile bakery enterprise had a number of flaws, as it turned out. I may well have covered these, and the mobile bakery, in a previous blog post; I can’t remember. Anyway, that’s not what this post is about.

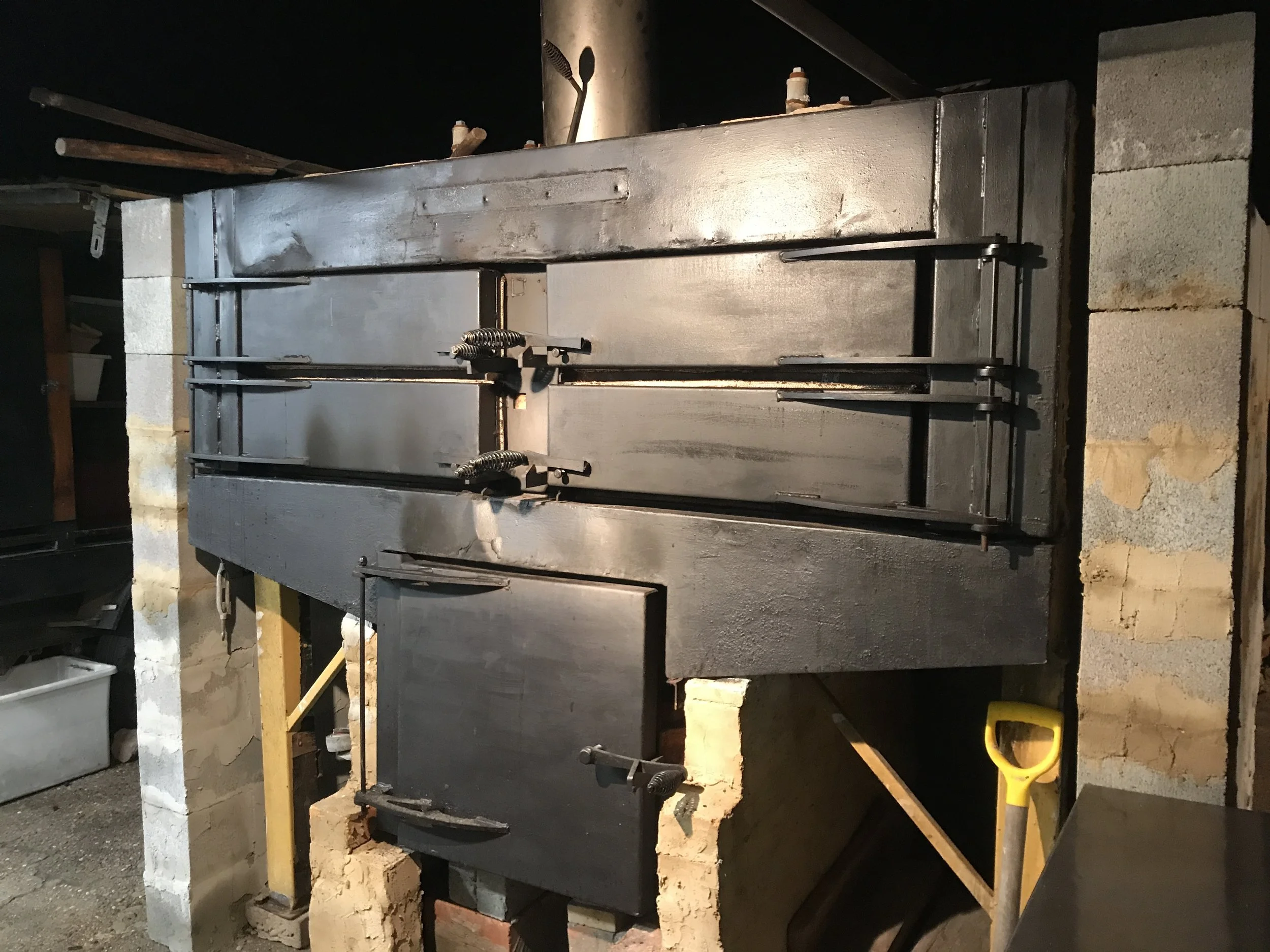

That’s Luna’s bush hideaway. She’s in the box…

Luna found her place as a stationary oven. She lived on a fixed site, still on the mobile bakery trailer, at a bush hideaway in Ellalong, where she performed the weekly baking duties for local Saturday markets with incredible finesse. I knew the difference Luna made - a kind of crust that only a brick oven can give you.

She was always a bit tricky to work with - she liked to be pre heated for a good 5 hours before she would really begin to sing, for example. She had some hot spots (which became completely ‘worked around’, as one does with any old bakery oven), and she needed a major clean out and overhaul every year, or she would block up (and actually melt) in parts. I had to rebuild the firebox a couple of times, and used a crowbar to open up a pathway for flue gases when it fatigued after about 5 years use.

I learned the hard way with Luna, every time, but after each rebuild she returned to work, better than ever. She was, for many years, a ‘work in progress’. She eventually became an excellent oven, capable of baking an average of 30 average sized full sourdogh loaves an hour - provided I was on my game - and more if someone was helping me. She did her job as a test bed and we improved our Aromatic Embers ovens as a result.

When the first Bush Bakery at Ellalong came to an end, I packed Luna up in the trailer, took out her bricks, and parked her in a nearby paddock, where she lived for a few months. I towed her here to the farm, and she was parked again for a few more months. We removed her from the trailer after the Tour Down South, and a boilermaker began the task of refurbishing her, with design modifications we had now applied to some of our other ovens.

Luna was my third prototype. I was the test pilot and outside design consultant. Actually, I became the crash test dummy more often than not. The first two prototypes, both named Bertha, turned out to be absolute pigs of ovens, but pigs which were made to sing for their supper nonetheless, thanks to my need to bake decent bread.

Bertha 1 in Cafe mode. Note bricked plate warmer on top!

Luna was different. We really thought about Luna - all our mistakes taught us what NOT to do. So Luna was a decent oven from the getgo - but she developed some long term issues. That’s why I was always working on her - she took a fair bit of tweaking to make her really sing, I can tell you! So when I left her in the boilermaker’s capable hands, I gave him my wish list - or at least half of it. I knew I’d be doing the other half myself.

This time I wanted to make the flame generated from the fire really stretch, so that it could do the job of heating more cleanly, quickly and efficiently. We needed to get the bottom decks more even too. Back in the day, the area above the firebox was always the hottest part of the deck. It was so hot that I had to set loaves to one side so they didn’t burn.

The boilermaker takes Luna apart with the tynes of a tractor.

Stretching the flame in Luna’s firebox.

The top decks have always relatively slow, so we set out to improve the heat here at same time.

The boilermaker built a more sophisticated and heavy duty baffle system, based on my ideas. He made the baffle itself more angled so that flame was siphoned off better when it runs against it from the firebox. I later bricked the inside of the firebox to further enhance the ‘flamethrower effect’. He rebuilt the firebox to include more brick than before. He also incorporated a whole series of cleaning access tubes to the roof of the oven, so that the area nearest the flue could be cleaned - an issue which had reared its ugly head a couple of times in Luna’s life already.

I’m hoping the changes to the flue system will eliminate the problem of soot build up altogether. I’m fully aware that I may simply be experiencing a case of wishful thinking here. Every designer wants their latest and greatest innovation to work - we always wear rose coloured glasses, to a certain extent. Sometimes, though, it pays to take out insurance. If there was still a build up of soot, despite our new modifications, at least I can now clean it out more easily than in the past.

Luna’s cleaning tubes before they get bricked and mortared.

All this work took many months. Luna was positioned in the middle of a paddock full of farm equipment. When the boilermaker was on the farm, he’d carry Luna’s bits over to the shed on the tines of the old tractor. He’d weld and angle grind and rivet for hours on end. From time to time I’d ‘lackey’ for him - just as I did when Luna was fabricated here on the farm years ago. Only then, as I remember it, I was on crutches. That’s a whole other story. Not this time - I walk pretty well these days.

More heavy duty thermal mass is added before putting Luna back together.

As the work on Luna slowly got done, a bit here and a bit there, the dairy shed also got finished - in much the same manner. A few weeks ago we carried Luna’s 2 finished pieces over to the dairy shed on the tractor, and we put her back together for the first time in a year. Then we positioned her outside the new school classroom and bakery, where she will live for quite a while, I hope.

Luna 2 showing inner layer of brickwork. This will be wrapped with besser brick.

I’ve been bricking her up, inside and out, for the past two weeks or so. It’s slow, heavy work, as a great deal of the brick is in really hard to get at places - inside baking chambers, for example. These baking chambers are only 16 cm high and a metre deep. One slides the bricks in on the end of a metal peel, and manipulates them as best as one can from a metre away. Around the baking chambers there are two layers of brick, and another layer on the top of them. Getting the bricks in place involves climbing up a ladder with brick or bricks in hand, keeping a fresh mortar on the go all the while, for maybe a couple of hundred climbs. Each brick weighs between 2 and 5 kg, and so far I’ve put roughly 500 bricks in and through and around the oven, as well as another couple of hundred inside the baffles, which we did before she was put back together. I’ve only done enough, at the time of writing this, to fire the oven up and make it work.

First layer of brickwork done. The oven is functional here, though nowhere near thermally efficient.

All this extra thermal mass and insulation will become necessary when Luna goes into production mode for the ‘Steady State Bakery’. It will operate as a heat sink, as well as a kind of heat mirror; the thick walls of brick should hold heat for days. Luna will become a super efficient oven.

i was inspired in my design for Luna by spending time at Harcourt Historic Bakery with Jodi and Dave when I did the Tour Down South last year. Their oven is capable of holding high temperatures for days after firing, as it has some 72 tonnes of brick around it. It’s an incredible piece of kit for a 100 year old oven. Dave manages to keep it hot with very little timber each day.

My version only will have maybe four or five tonnes of brick when it’s finished. The principle is similar to the oven in Harcourt though - get the brick hot, and then once it’s hot, keep it there for as long as possible. I’ll be looking for new bakery customers very soon, that’s for sure!

Next layer done. Still have to complete the outer wrapping, add more mass to the roof, and fill the besser bricks with rubble and sand.

Upon firing her up after putting her in place here, I saw that Luna was really a serious piece of flame art now. The firebox works a treat, blasting flame a good few feet each side, in sheets, spread out right under the two baking decks. It takes the oven from cold to baking temperature in just 3 hours, but will do it substantially quicker when it is fired each day or two, as it will retain a lot of heat.

Just a teensie fire here. When I fully blaze the fire, it’s too hot for my camera!

At the time of writing I’m about two thirds of the way through the brickwork. There is an ‘inner outer’ layer of brick around the baking chamber, and another around the firebox. There are two layers on top, with two more layers of grog based on mortar and recycled crushed concrete. There will be another layer of brick and mortar on top as well. There is a layer of besser brick surrounding the three sides, and I’m currently filling these with rubble, glass and sand to add thermal mass, as well as to use up everything I can from a demolished brick wall I was given. I’m going to fill a void between the inner and outer layers with insulation board.

My experience so far has been a bit different to what the world of oven builders has been telling me. One commonly held belief is that insulation like ceramic blanket or rockwool or ceramic board will ‘reflect’ heat back into the structure. While this is possible, there needs to be an outer layer of brick or thick mortar wrapping up the blanket in addition to the blanket itself for any reflection effect to occur. The blanket will eventually dissipate its stored heat in both directions - back in and out. If you wrap your blanket in brick on both sides, the blanket still fills with heat, but it slowly dissipates the stored heat back into thermal mass surrounding it. If you don’t wrap your insular material in thermal mass, you will ultimately allow 50% of the stored heat run out into the atmosphere. In addition, your insular material will actually be absorbing heat from the bricks next to it, contributing to a slower heat up of the oven itself. I learned this with Bertha 2, which took over 18 hours to heat from cold, and really only started to get useful after the second bake for the week. Needless to say, once I figured out our insulation mistake, I got to pull her apart and replace the insulation with brick, and this sped her heating time up by many hours.

The advantage of brick is that while it absorbs heat, it also reflects heat. If you sit beside a brick wall in the sun, you will experience how brick reflects heat. When it becomes ‘soaked’ with heat, it then becomes a heat source - it actually ‘radiates’. So you get reflection, absorption and dissipation (radiation) of heat, in that order. Brick, as a material to work with storing heat, becomes more efficient over time.

One uses ones loaf to make a decent loaf. Or so they say…

So far I’ve used the oven for my standard bakes, and have kept the oven warm over multiple days doing various tasks - slow roasting on one day and baking pizza on another. Luna can hold baking temperature without fire for a couple of hours at the moment. In fact, the top decks increase in temperature for the first six hours of firing, and continue to increase without fire for the next three hours. On some nights I have finished the bake and checked the baking chambers about 10 hours later, and they still held over 120 C. I think I can improve on this by a significant amount by just beefing up the thermal mass and adding strategic insulation in some places.

I’ve done the big stuff, now I will do the little things. Watch this space.

If you would like to experience Luna first hand, I run workshops for the general public each month. Professional baking workshops are held four times a year. Check out what’s on offer.

Post script:

Just a little update regarding Luna’s thermal performance. Since writing this article, I’ve filled in all the besser bricks with rubble, bits of brick and crusher dust. I’ve also enclosed a sleeve of air surrounding the baking chambers with brick. I’ve bagged the outer shell with mortar, and I’m half way through adding a layer of bottles covered in mortar over the top. Once this is done, I’ll paint the top section in black bituminous paint. At this point, the oven holds an average 100 degrees C some 12 hours after a full bake of about 80 or so loaves. It takes just a bit less than 3 hours to reach baking temperature from cold, though if I really want the oven to be fully ‘soaked’, I’ll pre heat for about 5 hours. I’m yet to gather data on how long the oven takes to heat from 100 degrees, but I think it should re heat in just a couple of hours. All the little bits I’ve done to make it hold heat longer are making a difference; and I can see I’ll be doing more as the need to use the oven more often grows with demand for bread. I’m also noticing that to heat the oven takes less fuel now. This is a bit unscientific, because I’m using different wood from around the farm, but the effect is still noticeable. I still don’t have enough demand to fill 2 days baking, but this will gradually build as I get out and gather more subscribers.

Reinventing the Reinvented

So here I was, camped on the farm in my caravan, waiting for things to happen with the dairy shed, which will become my classroom and bakery when it’s finished. I had all my bakery gear packed up. I didn’t have a bakery to put it in, but I did have the trailer, and a space in the shed where I could temporarily set up some of my equipment - the mixer, a fridge, a bench, and some ingredient storage shelves.

All I had to do, I figured, was to permanently install the traveling oven I took with me on the Tour Down South into the trailer, get the Coolgardie Cooler working better, and create a proofer on the trailer. Then I could bake at least a few dozen loaves at a time. This would be enough to make ‘a bit of dough’ while I was waiting for my new home to be built.

So I’m reinventing the reinvented, repurposed and recycled trailer. First it was a six by four, then it became my bakery shop and bread transporter, and then it became a mobile classroom and boudoir while I traveled the country, and now it was to become my semi mobile temporary bakery. I’m calling it the Bush Bakery II.1.

Getting the Cooler cooler

I figured that the issue with the Coolgardie Cooler was ventilation - it simply didn’t move air around inside enough for there to be any evaporative cooling effect. I decided to improve the ‘Coolgardie Coolroom’ by adding solar driven frictionless computer fans to the coolgardie screens, so that air would circulate quickly and constantly through them, and then inside the box. I installed a couple of vents to the outside of the trailer to assist with taking in air.

I had used a similar fan system in the Bush Bakery Mk I, which was adequate for holding dough cool for a day or so. Tried and tested technology, even less than perfect technology, is always a good option for me.

I purchased a 5V battery which could invert to 12 volts, and a solar panel which could be attached to the roof. I was aware that I was moving away from my ‘third world simple’ approach, which had guided me throughout the build of the Bush Bakery Mk II. Frankly, this approach had failed me with regard to the Coolgardie Cooler, so it was time to enlist some slightly more sophisticated solutions. Despite my extremely limited ability with regard to electrical wiring, the fans work very well. They will run for about 3 days without wearing out the battery. When the battery is plugged into the solar panel, running the fans rarely lowers the charge of the battery. It can be raining and cloudy for days on end and there will be no interruption to the ventilation inside the cooler.

Putting some vents into the Coolgardie Cooler

The screens in the side of the cooler were made from recycled exploded clay pellets wrapped in shade cloth, chicken mesh and hessian. I ran bleeder hoses through them so the clay could be moistened. There are hose outlets fitted so I can just plug in a regular garden hose to refill the screens with moisture. Once the screens are moistened, the fans can achieve about 5 degrees cooler than the outside ambient temperature. This isn’t enough to keep dough cool, but it shows there is an evaporative cooling effect. In future possible versions of this technology, I think I would make a lot more air move through the screens, as well as create a better plumbing system to hold water evenly through the vertical surface of the screen. For now, I have to add ice to the system to really make it work properly, particularly in summer. When there is ice in the cooler, as well as moisture in the screens, the Coolgardie Coolroom can bring the ambient temperature down by as much as 20 degrees below ambient. This is enough to keep dough cool for many hours at a time. I use repurposed plastic bottles filled with water and frozen as my ice supply. As long as there is a freezer to supply ice, I can run the cooler continuously.

Interestingly, making ice uses very little energy. If you have a domestic fridge and fill the freezer section with bottles of water, the thermal mass created as the bottles freeze actually reduces the amount of time the motor needs to run to keep it cool. I wonder if fridges harvest the cold from the freezer section to cool the fridge section - and if they don’t, why don’t they?

I gotta say, I reckon I’ve now got a ‘cool’ cooler. I’d given up on it during the Tour Down South, but with this new tweak it has become a useful piece of equipment. I can see myself modifying it a bit more down the track with the addition of more fans and more fins (timber fins to rest transit boards full of dough). Its capacity is currently just a trifle small, but I have plenty of space which I can use.

The Bush Oven installed on the trailer.

The Bush Oven becomes a weapon

Setting the oven up on the trailer in a permanent fashion was something I had been wanting to do since I was in WA on the Tour Down South. On the road, despite having all my tools on board at the time, it was just too difficult to do from a practical perspective. Now I was parked here in a paddock, it was easier. I designed the space for the oven to be postioned on the trailer to have an adjoining insulated box, similar in shape and size to the Coolgardie Cooler on the other side of the trailer. This would be warmed to become a proofer via a galvanised sheet of steel attached to the side of the oven.

The oven itself became wrapped in brick on five sides when I put it on the trailer. This was about a 400% improvement on the level of insulation I had when I set the oven up on its stand. This was the primary reason for putting it on the trailer. Theoretically, the oven would now become a very fast, well insulated baking weapon.

The first attempt at mounting the oven on the trailer was partially successful - it certainly baked a whole lot better than it did when I used it on the Tour Down South. The adjoining proofer was also a success. While it couldn’t create moisture within the box, it heated it very gently as the oven warmed up. I soon added a spirit burner stove with a saucepan of water to create steam. The proofer was very well insulated, and one load of water boiled at the start of a bake was enough to keep the proofer moist for a whole bake.

A Woodfired trailer?

My first serious bake using this setup was for a massive 90 loaves, which was during a 300 series workshop. While the oven held up to a continuous bake environment, a few hours after the bake was done I noticed a bit of smoke coming out of the trailer. The trailer actually had caught fire, and was well alight by the time I could get a hose to it!

Fortunately, I was able to put the fire out (thankfully I had a student, Jerome, hanging around after the workshop, who had a lot of patience and common sense - without him being around, I reckon I would have lost the trailer to that fire. Thanks Jerome!). It took a few hours of hose work to get to the seat of the fire, and to totally drench the trailer so it wouldn’t start again.

Adding a bit of fire blanket…

The next day I took the oven out of the trailer, and found that it had burned through the timber ‘floor’ below it. There was already 3 inches of brick under the oven, so I wasn’t expecting this brick to get so hot! I re installed the oven, this time with lots of fireproof insulation and more brick.

At the time of writing, I have re installed the oven a few more times, as I’ve built up my baking practice again. Each time I’ve refined the thermal setup. It’s now wrapped in lightweight concrete, brick and thermal blanket. And it is truly a baking weapon. It holds six loaves at a time, and can pretty much continuously bake an average of ten loaves per hour for as long as there is dough to bake. I rate this oven highly in my history of bakers’ ovens. I’ve probably baked in a dozen different types of oven over the years, and while this one doesn’t have the capacity of some others, it is great fun to use. The baker is working pretty constantly while using it, but for some reason it’s just very pleasant work. I’ve worked bigger ovens with much bigger throughput, and sometimes these ovens seem sluggish by comparison. This one is a little racing car! It requires constant attention, and can easily burn off the track, but if you keep an eye on things it goes very fast. It’s my pocket rocket.

The entire setup, the Bush Bakery Mk II.1, is also a baking weapon now. It’s very easy to control the bake, with a solar coolroom, a proofer powered by the oven, a dough area and ingredient storage all on board. I haven’t mentioned my new dough box, which is finally finished as well. It’s only used in classes, but it’s a great tool for making up to ten kilos of dough at a time. This piece of kit qualifies for another blog post! I truly now have an off grid bakery.

And now?

I’m currently in the process of doubling the output of the Bread Subscription Service. The subscription model is great because I can control growth. I take on new subscribers in a fairly planned way, in lockstep with the production capability of the bakery. The Bush Bakery Mk II.1 can comfortably bake 60 or so loaves in a session. This will be enough to keep things cashflow positive while my proper oven, Luna, gets refurbished.

My aim is to have a comfortable capacity of 100 loaves a day when the Steady State Bakery (see previous blog post) is properly functioning. This will be once again utilising my big girl, Luna. She’s currently having a rebuild by my erstwhile oven collaborator, Craig Miller of Aromatic Embers. Our expectation is that Luna will be a faster, steadier oven than she was. We’re adding a lot more thermal mass to her, as well as redoing the baffle system, the doors, and we are installing a bunch of cleaning access tubes to easily de soot her. I’m pretty excited about all this, and getting more excited as she nears completion.

As I write this entry, the dairy shed has internal walls built, some of the new ceiling done, a couple of doorways ready to have big glass doors put in, a new verandah roof over the back. The plumbing is half done, the wiring in place, and some of the insulation installed. There are soon to be two tradies working on the job, so it’s expected progress will hasten.

I do look forward to having my proper oven back, when the classroom and bakery in the dairy shed is finished. My life has felt like it’s on pause for the past six months, if I’m honest. The classroom section is getting done first, so should at least be ready in time for the next pro Sourdough 300 series workshops in May.

Subscribe, survive and thrive!

For now, I’m quite happy to bake a little bread each week for subscribers. The number of loaves baked and sold holds nice and steady. There is very little wastage. There will be growth, but in a very controlled way. Eventually 100 subscribers will be on board, as I believe the Steady State Bakery can handle these people’s total bread requirements fairly easily when it is finished. Currently I’m baking once a week, but I believe there could well be demand for another baking session or two in the schedule in the not too distant future.

Beyond this, I’m anticipating the dairy shed will be workable. Hopefully the growth of the subscription system will coincide with the work on the bakery and classroom here.

Watch this space for more about the new dairy shed, which will soon by my bakery and classroom, as it develops.

If you live in the Newcastle/lower Hunter region and would like to learn more about the subscription service I’ve now set up, here’s the link!

The birth of ANOTHER bakery - among other things.

The foothills of the Great Divide

Crossing the country and having this past year as a ‘sabbatical’ from baking commercially has led me to a number of realisations. The whole time, I’ve baked for myself and my students; I’ve had good bread to eat. Since I returned, though, something has been missing.

I’m addicted to my bread.

Addicted to bakeries?

Lets face it. I’m addicted to baking, and I’m especially addicted to my bread.

This extends into building actual bakeries so that I can make lots of the bread I really like to bake.

Like all addictions, it is multi leveled.

Firstly, I need to eat this bread. It’s like my medicine as well as food. As long as I have this bread to eat, the world, in my eyes, is okay. Even if I have very little money, I have nutrition - all I require is a piece of bread, maybe some cheese and tomato, and I am nourished. Other breads just don’t do it for me in the way mine does. Not to say there aren’t other great breads - it’s just that I’ve arrived at a very specific bread and I would like to keep having it for breakfast. And lunch, if possible. Occasionally dinner is okay as well.

Then, the addiction to the process of baking it kicks in. Baking provides a weekly rhythm, something to structure your day around. The process is its own reward - a good bake, and you are on top of the world. Of course, a bad one is somewhat less than ideal, and a number of bad ones in a row can be soul destroying. Luckily, there are more good bakes than bad ones.

Finally, the addiction to the financial reward can’t be ignored. When I bake each week, even just 30 loaves or so, there is cashflow. When you are a micro business, regular cashflow is everything. Before I moved from Ellalong, I was baking a few hundred loaves at a time, and this provided the bulk of my regular income. Now the weekly bake makes up a small but important part; teaching, consulting and training make up the rest.

Oh for a ‘Steady State’…and I don’t mean politics!

Some ideas pass naturally, while others persist - or more correctly they mutate in my mind.

I’ve been in the food business now for over 30 years - and for the past 29 I’ve been involved with bakeries and cafes. I’ve been wondering about energy use that whole time. I’ve experienced, lamented and deeply pondered food waste. Another issue to fill my grey matter has been wear and tear on bakery equipment.

After a while these three categories of problem morphed into a single simple solution. I want to establish what I call a ‘steady state bakery’. The idea is a bakery which produces the same basic amount every day. It doesn’t grade up production on one day to wind it down on others. It won’t be ‘market driven’ - like most bakeries are, as they surf the highs and lows of bakery production life.

I’ve written about this subject in earlier blog posts right here. Scroll backward and you’ll pick up multiple references.

All machines, and I’m including a bakery as a machine, are designed for optimal conditions of use. Then they are tweaked to extend the conditions to make them operate in real world conditions. When a machine is dynamic, it wears out more quickly.

A stable machine wears less, and consumes less energy. When a machine operates at the same pace all the time, stresses and strains are minimised on the componentry. They last longer and consume less energy.

Humans are different. They don’t mind work, but they need rest. And they need rhythm. Humans do well with a combination of routine and rest. Any human centered machine has to factor in humans.

My past two production setups have been specifically designed to supply weekend markets. This means that they bake large volumes on just one or two days a week. The rest of the time, they are either dormant, or being used for teaching, consulting or pre production work. So each week the machine gets wound up, stretched beyond capacity, and then wound down again.

A baker commits to the market each week, whether it is on or not. They work days in advance as they go about their routine, and by market day they are simply loading their freshly baked bread into their vans to meet their customers and to get paid for their work. If it rains and the market is cancelled; their payday just disappears. Then, the word wastage takes on a whole new meaning!

Every bakery has a lot of production variables; the seasons, new customers, wholesale business orders, local trading conditions, bakery competition, weekend markets and much more. Thus, all these variables inevitably lead to bread waste, and volatility.

A bakery, then, is usually a highly dynamic machine. Dynamic machines are prone to failure.

The ‘steady state’ bakery is different; it’s meant to produce the same amount of bread each bake - each day, week or month. It’s a machine with a daily rhythm based around repetition. It’s designed for a particular volume - nothing more. It doesn’t get ‘pushed’.

By doing this, there are many benefits. The machine doesn’t have to work hard - it just works the same amount each time to get the job done. Thus, the machine lasts longer and uses less energy. The more often it works, the less energy it requires in proportion to the output. The machine can be scaled up or down according to requirements, but in a planned way.

With a daily and weekly rhythm in a Steady State Bakery (SSB), there is a curious bi product; learning happens through repetition. The bake is a series of processes which are done at specific times, each with its own set of KPI. The only person who needs an overview is the baker. Through working with the processes, helpers gradually understand the overview; through learning all of the processes involved in a hands on way, humans involved piece together the whole picture, little by little. So a SSB is also a great environment for learning processes.

Another advantage of an SSB is being able to properly plan for the bakery’s resource use. Things like fuel, ingredient supply and freight all are best delivered in steady amounts, not only from the bakery’s perspective, but also from a logistics point of view.

Still another benefit is to be able to concentrate on reducing the environmental damage which a bakery can create. A SSB makes it easier to have a cause and effect solution put in place as there are no extremities to take into account.

Subscription baking - bread as a service

Every baker loves to set production levels to suit ourselves and our equipment. These levels should also enable us to make a crust. (:))

We have to find homes for all that bread we are baking - we definitely don’t want waste. As mentioned earlier, supplying markets leads to waste, one way or another.

To achieve steady production and sale of bread, with as close as possible to zero waste, I decided to set up a subscription system. Customers ‘subscribe’ to my baking and delivery service. By purchasing multiple loaves in advance, subscribers save money. They are bulk buying, with the convenience of having just a loaf or two delivered when they want it.

The bakery gets the benefit of steady customers and cash flow every week. And ‘planned by demand’ baking, so that only the amount ordered is supplied. The bakery works by the batch, the size of which is determined by the number of subscribers at any given time. There is always a degree of guesswork in determining the batch size each week, but the risk of wastage is reduced dramatically when compared to baking for a market which could be cancelled at the last minute.

My first attempt at subscription baking was about 8 years ago when the bakery was in Newcastle West. The model worked really well, but I moved into opening that bakery for retail business, and just outgrew the subscription model.

This time, the plan is to stick with subscriber based retail and incorporate it into the fabric of the School of Sourdough. A Steady State Bakery which is also a school, driven by subscribers.

In a bit of a departure from the original plan, I’ve included the possibility of resellers or ‘value adders’ being able to access the service. This means if you have a cafe or a shop or a food co-op, you can also subscribe. At the time of writing, we have two retail outlets on board, allowing the general public to buy bread on a whim. There is space in the system for more businesses to subscribe to the service, so those of you who want next level bread locally can get it without actually subscribing - all you need to do is to convince your local cafe or health food store to subscribe for you!

I’ll go into the new range of services in a separate blog post very soon. If you’re interested in becoming one of our Newcastle and Hunter Valley region subscribers, here’s the link!

Another Nullabor Crossing - and time to analyse the 'Erratics'.

The west had entered my veins. I was a long way from the Hunter Valley. Yet I felt at home. I understand now why Western Australians have a different presence, a kind of WA attitude. They understand how damn big this country is, because they experience it more often than maybe us East Coast folk do.

I decided to head back to Perth for a few more days. I had a bit more free time before I was due to embark on the return Nullabor crossing, on my way to Mildura, and then on to the central west of NSW. After that, home sweet home - which is actually not even built yet, so I guess I could look forward to more ‘glamping’ in my caravan when I got back. That’s a story for another blog post.

Perth is an interesting place. It’s like a kind of ‘tiny city’ - you know, in the same way that you can have a ‘tiny house’. It’s not quite a city, but all the props are in place. There are not that many people there - and they are really spread out. Perth is a collection of suburbs. A quick visit to the ABS website verifies this; while Western Australia has about a person per square kilometer or less in most places. Perth’s population density is going up. Drilling a bit deeper, the city population density is not that much less than Sydney’s per square kilometer, but the actual ‘city hub’ of Perth is about three blocks in area. You could crawl it from one side to the other and still have workable knees. While Perth has been growing, it is a captive of the mining economy - it’s a kind of ‘boom and bust’ town. The fortunes of the place are intricately tied up with the fortunes of the mining business. When I was there, the mining business was on the wane, so property prices were also on the wane. Nonetheless, the place looked and felt prosperous and on the whole, positive.

I was pretty enamoured with Fremantle. It feels a bit ‘make believe’, but it was a kind of make believe I could buy into. There was a thriving city ‘market’ economy - the whole place seemed to revolve around the Freo market, which operates four days a week; the town kind of spills out from the market and onto the marina and foreshore; or if you go the other way, into past millenia, a foot friendly village with a plethora of things like bookshops and curiosity stuff to explore. Cars were clearly not invented when they built this place.

So Freo was funky; a place where they have taken tourism seriously from a brand point of view. It’s has a working harbour, like Newcastle in the Hunter region (where I’ve spent the last decade or so). It felt familiar, but with the sun coming up and going down on the wrong side of the harbour. A great place to visit. Not sure how it would be to live there; more research will be needed. Not planning on relocating any time soon, but this side of the country has certain attractions.

After a few days relaxing and hanging out, I ventured back towards the Nullabor. I think I got a bit freaked out by the vastness of the journey - literally crossing the country again, with that bloody enormous plain at the beginning. Now I knew the distances involved, and was better prepared. Nonetheless, the journey home still daunted me. I hadn’t considered the final leg of the trip very much - bookings and venues for workshops were flowing in slowly for this part of the Tour Down South, but a fair bit of the organising was still not complete, as I was doing it on the fly, waiting for people to get back to me in many cases. Thus, I decided to cancel any workshops that didn’t have people booked into them as yet. This meant that I had plenty of time to get all the way from Perth to Mildura in NSW.

Perth campsite after a spot of rain - we got hammered!

One thing the Nullabor provides is headspace. Whether this is a good thing or not I’m not sure. On those long, grinding stretches of flat earth, my mind wandered around the cosmos of flickering thoughts in my head, looking for a thought to grab a hold of, and pull apart. Like the ubiquitous crows on the side of the tarmac, picking away at the recently deceased victims of the road, my mind struggled to stay with one thought long enough to get a proper feed.

It’s believed by those folk who gave us Cognitive Behavioural Therapy, that on any given day, we have somewhere in the vicinity of 50,000 individual thoughts - though many overlap with others. The thoughts we grab a hold of are the ones that set the tone for our mood - so if you grab a hold of the hard things, the things that aren’t resolved, or the things that can’t be resolved, you can end up in a bad mood, or even depressed. On the other hand, if we simply watch our thoughts go by, without attaching to any one of them, we remain productive and positive.

I tried to employ this technique, but found myself returning to the ‘too hard basket’ over and over again. I was that crow who finds a carcass on a busy stretch of highway. Every time he (or she) goes to get a decent peck of it, a car comes and he (or she) has to get out of the way, or risk being flattened. One of the things in this particular basket was the Erratic Bread Syndrome I’ve been documenting for the past few posts. Try as I might, I seemed to be unable to isolate any single variable. Was it the WA water? Was it my starter? Was it the flour? Was it my oven? Was it the firewood?

The analysis of variables wasn’t helping at all - there were too many moving parts to this particular issue for me to be able to confidently isolate any one part to have a proper look at it. So I began to compare what I was working with at present to what I usually worked with at my own bakery in the Hunter Valley. There were a number of things which were different. At home, I had refrigeration. I had rainwater. I had the same flour all the time. I had the same fuel for the oven (I purchased sawmill offcuts in large amounts, which gradually seasoned as the year progressed). In short, I had a pretty consistent setup. This meant that I could change one thing and see the effect straight away. Or, if something like the weather changed, I had the ability to mitigate the effects via refrigeration and timing.

Timing. I hadn’t really looked at timing. I have all sorts of charts which I’ve gradually developed over the years at the bakery. These charts gave me a pretty good idea of how long dough takes to ripen at different temperatures, and at different stages of the proofing process. They weren’t super accurate, but in constant conditions they worked well. I didn’t have constant conditions now. I had ambient temperatures, and these varied quite a bit. I could knock five or maybe ten degrees off the ambient temp using ice and fans in my Coolgardie Coolroom, but this wasn’t enough to really get control of the leavening process.

I was aware of an issue with regard to the time I made the dough for the classes. In order to get some fresh bread out of the oven by the end of the workshop (in winter), I needed longer than 8 hours for the whole process, yet the workshop was only 8 hours long. I hadn’t been able to make dough a few hours before the class began, because this would mean making dough before first light. While this was achievable sometimes, more often than not on the road it wasn’t. I often didn’t have anything more than torchlight to work with; I also had to fully set up the bakery to make dough - water, benches, flour and so forth. When camping in caravan parks, cheek by jowl with a neighbour, the sound of me banging around at sparrows fart wasn’t something the neighbours took kindly to.

In addition, usually I would have to tow my trailer into the venue just before the workshop and set up. I then had to assemble the portable oven and generally work fast to get it all done before people arrived. I rarely had access to venues the day before; if I did, I would make the dough in the evening before I went to bed, The plan was to keep it cool overnight so that it would be optimally ripe for the class the next day. If it was a cold night, the dough kept. If it wasn’t, the dough would be on the edge of being over ripe by the time we would get into it with the group. So here was something I hadn’t properly thought through in my planning, and it wasn’t something I could easily fix.

Another bloody variable! Timing! I was kinda hoping to get to some resolution of the issue as I crossed the Nullabor, but instead I was adding in more complexity.

It was easier to angst over other things. It really was. So my mind went through all sorts of stuff - you name it, I thought around it; relationships, the state of my vehicle, the health of the animals, my kids, my family, the weather, my own health, reviewing the trip, money, what I will do when I get back, and on it went. Fifty thousand thoughts each day.

It takes at least three days to cross the Nullabor. It takes another three days to traverse the rest of South Australia, and then another day or two to cross into NSW. I considered doing a quick trip up to Broken Hill, but I had a full group at the Mildura workshop, so I decided to save that for next time.

Red Cliffs farming on very dry land. These are Joanne’s pistachio crop. Pistachios grow for 100 years!

Crossing the Murray river provided me with my first actual desert experience. The Nullabor is a plain, not a desert. Life is everywhere, intensely, on the Nullabor. But crossing back into South Australia, right next to the Murray river, I got a taste of actual desert. This surprised me. I was heading into Berri, the fruit and wine capital of the country. I was looking at vast areas of flat land, which once grew fruit or grapes. Not any more. Now it’s a vast empty place. I was confronted by a dust storm so thick that vehicles had to pull over till it passed. It was a struggle to see further than the bonnet of the car. It was intense. I got the feeling that this was a desert made by man. It was brutal.

Some of the team at Red Cliffs Community Centre. That’s Joanne on the left.

My next workshop was at Red Cliffs, just outside Mildura. A lovely little town, with civic pride flowing through its veins. I was meeting up with Joanne Farrel, who ran the local community centre, along with many other community ventures. She was a tonic after the journey I had just survived - down to earth, practical and clearly a community asset. We had me all set up and sorted out in her back shed within a few hours, and I was keen to get some preparation happening for my next workshop, after thinking about it for the past week or two amongst the fifty thousand other thoughts I had been observing per day as I traveled.

The Bush Bakery, out in the shed at Red Cliffs

It was a great workshop, with keen locals picking my brain in every direction. The bread was better - I had purchased some block ice locally, which meant that I could keep my dough sufficiently cold to get it through the workshop without breaking down. So this was an improvement. Perhaps thinking about timing was helping - either that, or that bloody big block of ice!

This flour mill in Temorah no longer operates, but they’ve kept the lettering fresh!

I had a bit of time up my sleeve before the workshop in Bathurst, so I decided to swing through Temorah on the way. I had been there only once before, some 40 years earlier. Back then, it was a tiny outpost ‘hanging on’, as best it could. I was surprised to see how the town had changed and adapted - if anything, it was a thriving small town now.

As the trip wound its way through lots of small and medium sized country towns right across the country, I started to get a sense of how different towns and regions cope with change. Many of them have given over to the relentless shopping mall - these towns seem to have lost a bit of their soul as a result. The mall sucks the life out of the main drag, and these places look and feel like every other place. Uniform, featureless. Samey.

Not Temorah though. It has embraced its history, and resisted the urge to allow the corporates to reinvent the place. You can see it in the way the town still has a viable main street. Lots of old buildings, remnants of the town’s history, not only still stand, but have been tarted up a bit, despite their function no longer being required. For this reason, Temorah still feels ‘real’. I felt heartened by this.

It was late August. The weather had been gradually warming up, and I thought the worst of winter was behind me now. I was wrong. When I got to Bathurst, I set my ‘boudoir’ up at a mate’s little farmlet at Dunkeld. I chose a spot out the back overlooking the rolling hills. I hadn’t expected to be brutalised by cold, but one night there and I had my tail between my legs. The temperature dropped to below zero overnight, and in the morning I stepped out to find the ground was covered in sleet. The creatures, particularly Mishka, were not impressed.

This is what a frozen tarpaulin looks like.

It was a bit of a surprise, as I’d already rolled up the extra blankets, thinking I wouldn’t be needing them. Me and the creatures had spent the night huddling together for warmth. Lesson: never take the weather for granted.

Bathurst is a larger regional town - quite spread out these days - but somehow, despite the aforementioned ‘corporate mall sprawl’, it has retained its character. The main streets are wide and interconnected, and the city seems to have retained its heart. I went to school there back in the 70s. My memory of the place back then isn’t all that positive - it was smaller, but kind of disjointed. It still is, in a way, but it retains its unique character, and that’s nice.

They have a great wholefoods co op there, and there seems to be a bit of an ‘alternate’ community growing along nicely in the town. I had originally planned to run two workshops there - one at the food co op, and the other at a place called the Rahamim Ecology Centre. I hadn’t seen the food co op before I visited this time, but upon inspecting the venue, I could see it was going to be difficult to set up there, due to my lengthy set up process. The food co op was inside a small shopping mall, and getting the Bush Bakery and Boudoir in there with my animals, my trailer and me was going to be a stretch. I wanted to avoid setting up before dawn, so I needed to camp there to have enough time to set up. I decided to combine the two workshops at the Rahamim Centre instead.

The Bush Bakery at the Rahamim Centre.

The Rahamim Centre was just out of town, at a church sanctuary. It had a working permaculture community garden, a lovely outdoor BBQ and pizza area, and it was really easy to access with my trailer.

Prior to the workshop, I made a small batch of dough at my friend’s house and baked it. Very ordinary bread resulted, leaving me less than confident that all my analysis was getting me anywhere at all. I was feeling incredibly disheartened, and still confused as to what was going wrong!

The workshop proceeded well despite my feelings. The bitter cold, though, crept in as the day progressed. We were outside, and despite a ferocious fire in the Bush Oven, keeping warm proved to be quite difficult. It took me straight back to school days, and memories of Bathurst’s brutal winters. Baking in this weather brought challenges that I hadn’t had to worry about for a while, but everything seemed to run smoothly, and we got reasonably good bread out of the Bush Oven, well ahead of the finish of the workshop. Once again I was unable to really get a good ‘bloom’ out of the dough - despite my best efforts at timing the whole process correctly.

By now, though, the jigsaw puzzle of variables was slowly starting to make sense. Just as well, too, as it was the last workshop of the Tour Down South!

I looked at the list of variables so far. The starter was good. The flour was consistent. The water was fine. The timber for the oven was well seasoned and flamed well.

On the other hand, timing was difficult here, as the cold weather meant that dough ripened slowly. I had made dough the night before, and this dough ended up being at least twelve hours old by the time we processed it. While I couldn’t accurately record the temperature over the entirety of the first proof, it was somewhere in the vicinity of 15 to 20 degrees on average for the time it was stored.

The sponge, or pre ferment, was made with very cold water (hot water was a hassle from a camping point of view) and while it was partially active when I made the dough, it could have had significantly more time.

And in the extreme cold, the oven’s lack of insulation showed quite dramatically. The shape of the loaves wasn’t ‘even’ - a problem I hadn’t encountered since Tiff’s place at Esperance. This could only mean that certain parts of the oven weren’t getting as hot as others. They were higher at the back of the oven than they were nearest the door.

My take home message from this bake, and from the last section of the Tour Down South, was the Bush Bakery needed to have better temperature control. The Coolgardie Coolroom was, at this time, a failure; it couldn’t bring the dough down to ten degrees C or less, and I think this would have been optimal for timing things to work in a one day workshop setting. Had I been able to make the dough at 3am, for example, things may have been different - but when your baking day starts at 3 in the morning and finishes at 6pm in the evening, it’s a bloody long day! I refused to destroy myself for the sake of a few loaves of bread! Been there, done that!

The night lights of Bathurst from the Bush Bakery.

Temperature control would also have solved the starter ripeness issue too. While I believe the starter didn’t suffer as badly as a result of being held at between 15 and 20 degrees C most of the time when compared to how dough fared at the same temps, it still meant that I had to feed it more often than was ideal. Dough starter keeps fantastically well at cooler temps - below 15 at the very least - and performs best when it’s nicely ripe. I’m forever telling my students NOT to overfeed the starter! Without proper cooling, feeds had to be more frequent, and this in turn caused the ‘bed’ of ripe starter to vary in size quite a bit. As a result, the starter tends to become a bit less acid than ideal.

The Coolgardie Coolroom couldn’t bring dough temperatures down enough for overnight storage. Why was this important? Well, at 20 degrees, a dough will ripen in about 6 hours or so. My dough, on this occasion, had gone for 12 to 15 hours - way too long. Because of the cold ambient temperatures, it didn’t actually ‘break down’, as it might have done in summer, but nonetheless it was pretty much spent by the time we cut it.

Another important take away from all of this is to keep a proper Baker’s Diary, particularly when you are experiencing changes to your baking routine. I teach this all the time, but it seems I hadn’t been heeding my own lesson on this trip. Had I kept detailed records of everything that was happening, I think I could have got to the bottom of the problem much sooner than I did.

In the diary, one needs to record the time when different stages in the process take place, from pre ferment to finished loaf of bread. You also need some temperature data - ambient temperatures (approximate) as well as internal dough temperatures. You need to keep details like general observations as you work through the process. How does the dough feel? Did it feel ripe when you cut it? Was it stiff? Did the flour hold more water than usual? What type of flour are you using? Details. Keep it brief, and keep it in a format that’s easy to reference later. Record things like the date, season, flour types, and if you use different formulations, record which ones you are using. It’s hard to do this stuff when your hands are covered in dough, and it’s inconvenient sometimes. If your process is sorted, and you rarely change it, make sure you have a templated version of your process written down. You don’t have to make diary entries every time, especially if little changes between batches - but if there are changes, it is especially important to note them. Otherwise, like me, you might spend a lot of mental energy trying to figure stuff out. The brain is faulty, from a memory perspective, which is why you need to make sure you have written it down! In my case, I waited until I was thoroughly confused before I began to break things into bits and pieces - and as someone who has done this for 30 years, well, I should have simply assumed that with all the changes I was making, there was going to be a problem or three.

Another thing for me to work on was my oven. It did work quite well on the trip, but because of the need for it to be lightweight, a lack of insulation and thermal mass made the oven perform differently in different weather conditions. I would never have expected this to have as big an effect as it did, but now I’m looking at it again with the benefit of hindsight, this was a factor in the Erratic Bread Syndrome.

Now that I had crossed the country and returned in one piece, and the Tour Down South was pretty much done and dusted, I could assess things more carefully. As Rob from Perth said, it was a ballsy (foolhardy?) thing to do. Most of the ‘completely off the grid’ technology I chose to work with in my setup - the bakery trailer with its Coolgardie Coolroom/ spirit burner proofer, the wood fired Bush Oven and the rest of it - was completely untested. Add to that the double function of the trailer as my ‘boudoir’ along the way, being towed by an 18 year old Toyota Landcruiser, and you have a recipe for, at the very least, adventure. Most of my inventions worked reasonably well, with the exception of the Coolgardie Coolroom (and I have since redesigned this with a degree of success).

On the Tour Down South, I had traveled some 14,000 kilometers across some pretty harsh and unforgiving country; I ran 13 sourdough workshops for a total of about a hundred people; I did a demonstration bake, and two bakery consultations: I took my animals along for the ride, and camped in a totally self sufficient way the whole time. I made running repairs and improvements to everything as I went, and by the time the tour was done I had ironed out the functional issues around the setup I had designed and built.Oh, and along the way I baked a couple of hundred loaves of bread as well!

I set myself a particularly tricky brief, especially when you add the extra challenge of the Bush Bakery being made almost entirely from recycled or repurposed equipment. My animals and I survived. We all ate, slept and played well. I got to hang out with some dear friends all over the country, and there are a whole bunch of new home bakers now who have begun to make great bread themselves. The ideas which drove me to do this have been tested, reassessed, and passed on. I learned a lot about my craft, and about myself. I saw parts of the country I probably wouldn’t have in other circumstances, and I did it all on an absolute shoestring.

The Tour Down South, and the story about it, is now ‘a wrap’. If you’ve just picked up on the story, please take the time to wind back a few posts and read the whole thing - it’ll make more sense. In future posts, I’ll show you what I’ve now done to the Bush Bakery to make it a fully functioning off grid mobile bakery. I’ve been using it this past coupe of months since I returned as my micro bakery, while I await the finished construction of my new (stationary) bakery and classroom here in an old dairy in the hills of Wallarobba.

Thanks for hanging in to the end! I hope this story has inspired you to do something crazy as well!

Coming to grips with 'Erratic Bread Syndrome' at Yirri Grove

The Nullabor, twisted by me, in a camera.

The final workshop for the Esperance leg of the trip was held at Yirri Grove Olive plantation, out on the other side of good old Esperance.

I love the twist and turns of this journey; how they continue to surprise me. Plain sailing was never the objective of this trip. Nor was it expected, with an eighteen year old car and a recycled bakery shop being towed about fourteen thousand kilometers while crossing the seventh largest continent on earth. Not to mention a Kelpie canine and a Burmese feline who both ‘volunteered’ to ride with me. Esperance

We’re going WHERE?

(It was an open discussion between us. I did the talking and they did the listening.)

The Tour Down South was to dive in a deep pool of unknowns; and to have a go at something I hadn’t done before.

I often delude myself that I have been the inventor of lots of things in the bread world, or that I was the first one to do a particular thing. Pretty much every time I begin to think this, somebody from the other side of either the world or Australia lets me know that in fact this thing has been done centuries ago. Nonetheless, I’m still pretty sure I’m the first person to take a wood fired bakery across Australia and back on a six by four trailer. Please, prove me wrong!

One of my clients in Perth called my idea to do this trip ‘ballsy’. At the time, I wondered how he could see it that way. I mean, a coolroom powered by the breeze, and a wood fired oven, some flour, some firewood. No water. What could possibly go wrong? And if something did go wrong, well, I could turn to YouTube for help, like everyone else does. Or Instagram. Or Facebook.

We are never alone, even when we are in the middle of the Nullabor.

(Except, of course, there is no internet in the middle of the Nullabor. ‘Null’ means ‘none’. We are not talking a little ‘none’ here either. We are talking a big ‘none’. You have no idea how big ‘big’ is, but I’ll return to that idea later.)

Now I was on my way to Yirri Grove Olives, where Anne O’Neill ran a small plantation and pressing facility. They also have a cafe there, just past the wetlands of Esperance.

This is a place where there is a sign on the side of the road which keeps drivers updated daily as to the condition of the roads in the area. It’s not uncommon to lose a road or track due to various reasons - the tides, the changeable (and very windy) weather and so forth. The sign at the edge of it helps locals and visitors keep up to date on daily conditions.

I’m ushered into a large awning behind the cafe, plenty of space for the Bush Bakery MkII and my coterie of creatures. Being protected from the elements in this elemental place was a relief.

We are immediately accosted by a noisy crew of guinea fowl, who come charging down to the fence beside the awning to let us know they were on the job, and not to try anything stupid. Immediately, my kelpie Pippa is fascinated. She’s a cattle dog, and these are like cattle fowl. I think she was impressed. Or confused. Or both.

Here’s Anne, looking blurry. That’s because I’M blurry.

Anne and her husband are truly the most welcoming folk I think I have ever met. From the moment I arrived to the moment I left three days later, I was embraced like family. This experience of ‘welcoming the stranger’ has proved to be a profound one for me. Everywhere I stayed across the continent, I felt like a stranger; and yet, was welcomed almost universally. There were exceptions, which may well be expanded upon in some other blog at some other time. On this night, me and my family of furry friends were made welcome. We rested well.

The time gap between workshops was minimal. It took me back to ‘working’ as a musician back in the day. Pack it up, and set it up again somewhere else. Do it fast, and do it efficiently, so you can do it again. Breakfast hospitality was new, and welcome - so much so that before I knew it I had another dozen keen bread makers waiting on me to finish setting up!

At this workshop, I stumbled on another clue which would eventually lead me to solve the riddle of the ‘Erratic Bread Syndrome’ which had been plaguing me of late. For the past few workshops and bake offs, I had mixed results - which have been discussed in this blog on numerous occasions. Some breads I had baked along the way were okay, some were pretty good, and some were atrocious. I just couldn’t seem to get it consistently right. It would have been easier to solve the problem if the bread had been consistently bad - but the mixed results made it harder to work out where the issues were.

Thus far, I had observed that my list of variables was huge - variable flour, variable water, variable temperature and variable weather. Indeed, the entire trip had been one variable after another. So my breads were simply following suit. But how could I grab this thing by the tail and get control of it?

I was pursueing this process of ‘reducing variables’ when it occurred to me that the age of my starter between feeds was also a variable. I would sometimes go a couple of weeks between bakes, and as such I would simply keep the desem (dough starter) cool as best I could - but feeds were fairly irregular, and temperatures varied quite a lot as well. My ‘coolgardie’ style evaporative cooler was next to useless.

The first incarnation of the ‘Coolgardie Coolroom’.

(As you might not have been following this story, I’ll explain. I designed the Bush Bakery MkII to be as ‘off the grid’ as possible. I reasoned that a simple evaporative cooler, a la the ‘Coolgardie Safe’ crossed with a ‘zeer pot’ would work well enough to store dough and sourdough starter in the middle of Winter crossing the desert.)

I went through lots of evolutions in thinking about this idea of an ‘evaporative coolroom’, until I ended up with something that was capable of being both a cooler and a proofer. It had expanded clay balls from an aquaculture setup contained in screens along the walls, which were filled with water via a bleed hose. The water, theoretically, evaporated from the clay pellets via airflow, which came through the walls as the trailer moved through the air. It was like an automatic evaporator, which was supposed to reduce the temperature of the air.

When I wanted to 'proof’ (warm) the dough just prior to baking, I simply added a spirit burner (a ‘trangia’ alcohol burner) and a plate of water mounted on top, which warmed up the box and created steam. As far as this side of the equation was concerned, the proofer worked a treat. The cooler, on the other hand, could at the very best remove 5 degrees c from the air temp. I concluded that there wasn’t enough air flow to really circulate the air. My plumber’s skills were also lacking, as I couldn’t get the bleed hoses to work properly in the screens.

THe ‘Coolgardie Coolroom’ in proofer mode.

As I write this blog post some months later, and I can tell you that I’ve now made the cooler work via a small solar powered battery and some low friction computer fans mounted in the walls. These work pretty well, but when I was on the road the ‘coolgardie coolroom’ side of things was an impediment. I had resorted to purchasing ice on a regular basis to keep starter and food cool on the road. This meant that the starter could swing from under ripe to overripe quite quickly.

As I traveled, there was not always the facility (decent water, relatively enclosed space and good weather) to set up the mobile bakery and feed the starter.

The starter had been fed just before the last bake at Bread Local. It had been getting quite a bit of a workout, actually, with three bakes in just a few days. So that eliminated another variable.

In the workshop, we made dough as a group, using a few techniques which enable people to be able to make dough cleanly almost anywhere, including out in the bush where there might not even be any table! Our doughs worked really well, though were not ripe in time to bake in the wood fired oven.

Because I had been experiencing ‘Erratic Bread Syndrome’, I pre made some dough the day before the workshop so the students could bake it on the day. This was like a kind of insurance policy; the dough may go off too quickly, or not at all, so ‘here’s one I prepared earlier’ came to be my primary backup. I also shaped some dough ready to bake; I really didn’t expect it to last in the faulty cooler. When I checked it in the morning, it had skinned, and, miraculously, somehow it seemed to be in good condition, beyond the skin that it had formed. The ‘skin’ is normally a negative, but in this case it was holding the batards together in the cooler.

As I mentioned earlier, there were lots of layers of preparation for this class - I was determined to remove baking risk. We baked various stages of dough that day, fresh dough, overnight proofed dough, and pre formed dough - unsurprisingly, with mixed results. Some were okay, but there were also some flat ones.

The mystery deepened. It didn’t seem to matter how much preparation I did - how many ‘insurance policies’ I made to ensure I had some decent bread for my students. I still was having failures, and that meant I was still struggling to figure out which of my variables was causing the problem.

I had removed another variable as well - I had returned to using Wholegrain Milling flour, thanks to Tiff using it at her bakery. I knew wholegrain milling’s flour, so I bought a bag from Tiff’s supply (thanks Tiff!) before I left. Prior to this I used whatever I could get at the local supermarket. I was confident I could work with many different types of flour, but this was proving to add a variable.

So two variables eliminated now.

Water, temperature and weather remained variables to be dealt with. I may never get on top of the last one; but if I do, there’s an excellent subject for another blog post!

It seemed like I had still had numerous problems, all at the same time. It never rains, as they say. Until it pours.

The Bush Oven, insulated by the use of some firebricks and terracotta pots placed on top.

I was becoming more aware of the limitations of my Bush Oven. It had very little insulation, and so was dependent on constant fire to achieve good results. In a workshop situation, this is a hard ask, as it can become a full time job just keeping the fire at the right pitch. I can rarely do both things - keep a fire running well and teach a group of people - simultaneously. Often, a compromise involving intense fire activity interspersed with none whatsoever, was reached. Not what the scientist in me would call ‘consistent’. So add this to the ever growing list of variables in my current baking practice. Occasionally I would delegate a member of the group to this task of ‘keeping the flame that never will die’, but the finesse involved ends up becoming too much for the student. They too struggle to attend the class and run the fire at the same time. This technique was also flawed, but it did help when I had a good firekeeper.

Just another variable to absorb in the problem solving process - firewood!

To add to this, different locations offered up different timbers. This place had a legendary fuel, mallee root, which many people rave about. I used to have access to it in the Blue Mountains from time to time - we had a firewood fetcher fella who would bring it down every year for us, and with my slow combustion fuel stove (which warmed the house at Medlow Bath back in the day), Mallee root burned as hot as coal, and as long lasting. I thought it was amazing, and got it whenever our wood fetcher had it. This time around, though, my little baker’s oven didn’t like it at all, as it generated lots of hot coal. The Bush Oven (in fact all of the ovens I’ve designed), prefers flame. The flame pushes the flue gas more efficiently all the way around the baking chamber. Hot coals, on the other hand, tend to make the bottom deck too hot, and the top deck gets too cold.

Some timbers are better at delivering flame than others, and these were not always plentiful. As they say; ‘You pays your money and you takes your chances’. So yes, firewood quality was another variable I had to deal with.

Reduce two variables, Starter and Flour; and discover another two, the Oven and Firewood. Two steps forward, and two steps back. Could it be that I have discovered the ‘Bakery Two step’ ?

After the workshop, I decided to process some of the leftover dough we had made that day - I had a hot oven; why waste the heat? I asked Anne and her husband to swing by later for an extended bake off. The oven had been running for many hours by now. I processed the dough through the second proof, and shaped some dough the students had left as well. By the time Anne and her husband came with wine and cheese and, of course, olives, all the dough had been shaped and was proofing nicely. I baked off some mini baguettes and some batards. All were sensational. The shape held, and the crust and crumb were both very acceptable. It had been the best bake I had done since before Perth. So what was I doing right?

Mini Baguettes and some batards.

We already established I had fresher starter. So one variable didn’t play into the results of the day. Secondly, I was now using consistent flour, rather than whatever I could get at the supermarket along the way. Another variable under control. Third thing: the water had changed. Some of it had been filtered and treated with light, which was how it worked here at Anne’s orchard, and this tasted pretty clear. The water I had used throughout the west had tasted like clay, almost without exception. Some of the dough made at this workshop was made using ‘clear’ water; but some of it had been made a day earlier, which hadn’t been filtered in the same way.

Thus, the quality of water wasn’t necessarily part of the solution here. Nonethless, if I was going to solve problems, understanding all the variables was essential - it was a large list, and getting larger and more complex as I went along. Changes in water quality were still a potential contributor. So I filled all my tanks with this clear water. I had about 60 litres all up, so this would have to last me until the next time I could load up with good water. I had a trip across the Nullabor, and my next workshop a full two weeks away, near Mildura back in Victoria. So I was most likely to use most of this water before I would make dough again. At least this time, I would have nice water on board to cross the desert!

(Last Nullabor crossing, the water I drank was ‘whatever was available’, - hadn’t allowed for enough storage capacity on the trailer - local water was often undrinkable. I had since added more water storage.)

I still managed to reserve about 10 litres of clean water for dough in Victoria, so that keeps that variable at bay for a little while!

So at Yirri Grove workshop it was back to Great bread. Since I’ve crossed the border into WA, it’s been Crap bread, Great bread, Crap bread, Mediocre bread, Great bread. The Erratic Bread Syndrome continues.

With two variables removed, another mitigated against, and quite a few more identified, I was actually feeling like I was making forward progress. Onward across the Nullabor one more time. I had the mental strength necessary to do it this time. I was getting used to life on the road. It was making me stronger.

Esperance with BreadLocal - and I'm all mixed up!

So it was off to Esperance. I’d been averaging a workshop every couple of weeks so far. Suddenly I was flat out. In Esperance I had a busy itinerary, with two Bush Baking workshops and a demonstration bake to do; all in the space of about a week. In addition, I had to cast an eye over BreadLocal’s home based microbakery.

BreadLocal is the brainchild of Tiff Brown, who came to study with me some years back. She has continued her study of bread and pastry production processes in multiple countries over the whole time, and now creates sourdough loaves and croissants which are second to none. I was looking forward to catching up and seeing what was going on for her production wise. She had a few questions and things to try while I was there. It was going to be a fun week!

Tiff runs her bakery on a Market Master woodfired oven which was designed by Craig Miller and myself. Hers was a late ‘pre production’ prototype, but you wouldn’t know it. It is a very well thought through piece of wood fired cooking equipment. My own oven, Luna, was the third generation prototype which, via a couple of other ovens, led to this one. Campared to mine, Tiff’s oven is streets ahead.

The Market Master firebox blazes!

This was the first time I had ever seen her oven in the flesh, though Craig always sends me plans and fabrication pictures. There in Tiff’s nearly complete bakery, the Market Master looks formidable. I’m immediately jealous.

Tiff had been having some issues with steam generation in her oven. The system Craig developed has evolved from the one I have in my oven. Hers is certainly a better looking setup, with nice stainless water cylinders and proper plumbing. Tiff, however, wasn’t happy with it. She needed substantially more than the oven was generating.

Tiff loads from bannetons ready for scoring.

We gave the oven a run the following day, and I was going to have a look at this issue. Tiff was also interested in exploring ways to make her baking more child friendly.

Tiff’s setup is at her home. It’s a converted garage, with two kitchen spaces - an oven room and a dough room. It’s been really well thought out, and built to a high standard by local tradespeople. When I arrived, the place was a flurry of activity, as these tradies were flat out getting the dough room finished in time for the upcoming workshop. To make matters a bit more complex, Tiff had also organised a rather large catering gig at her family’s farm just out of town on the weekend.

Oh, and did I mention that Tiff was also about 6 months pregnant; with a small (but delightful) boy (Ned) who was heading towards eighteen months when I was there? Yep. (Or, as Ned would put it, ‘No way!’)

Tiffany isn’t your normal baker. Indeed, she’s in a league of her own. Over the coming week I observed her super human powers gradually emerge.

Part of the mission for us while I was there was to explore ways she could make her baking session each week more ‘family friendly’. Her one full day each baking week had become a bit long, and Tiff wanted to work out a way of alleviating this issue before she had two little people to hang with very soon. I’ve been an advocate of the retardation process for many years, and Tiff had seen it in action at my place, so the plan was to see if it could be worked into her routine.

While I was there, we were also going to experiment with her oven. Tiff had been mainly using the top deck, as the bottom was too hot. The idea here was to figure out if using the bottom deck was at all workable in her typical bakery routine.

Meanwhile, I was prepping for my two workshops and demonstration bake (which was at the catering event I mentioned earlier). Part of Tiff’s idea was to make sure I had plenty of gigs to help pay for my trip there. For that I was eternally grateful, as this trip was expensive to do. The distances involved are enormous, no matter how you travel - by air or land, there is a cost.

Esperance, for anyone who is not familiar with the area, is on a remote piece of coastline in Western Australia. It’s a minimum of four hours’ drive from Esperance to the nearest proper town. It’s 3420 kilometers to my place from there. It’s a pretty place, with pink salt lakes, coastal wetlands, beaches, and large swathes of wheat country all around. Beyond that, you are going to be crossing the desert to get there. But wait; there’s more! It’s also a busy little tourist hub, and a grain focused port is a vital part of the town’s mixed economy.

I love port towns.

Esperance is a most unusual, diverse place. Farming, salt lakes, wetlands, coastline, tourism, the port, and I’m sure there is more in the mix I haven’t been able to touch on.

Tiff is a very accomplished organiser, and she had decided to have a go at catering for a hundred people in an old wool shed on her parent’s farm while I was in town. It became increasingly clear to both of us that she had a bit on her plate. I did too - though for entirely different reasons.

We busily worked our way through the week; her extended family all converged on the house and attended to an enormous list of coordinated activities painstakingly worked and re worked by Tiff as the week unfolded. We worked our way through her bake, and were successfully able to use the bottom deck. However, surprisingly, using both decks actually slowed her down. Tiff believed she was able to bake faster with only the top deck. This amazed me, but I could see what was happening, and she was definitely right.

Loaves after ‘shuffling’.