The saga of my new wood fired oven

Shock Horror! Luna the wood fired oven has been decommissioned!

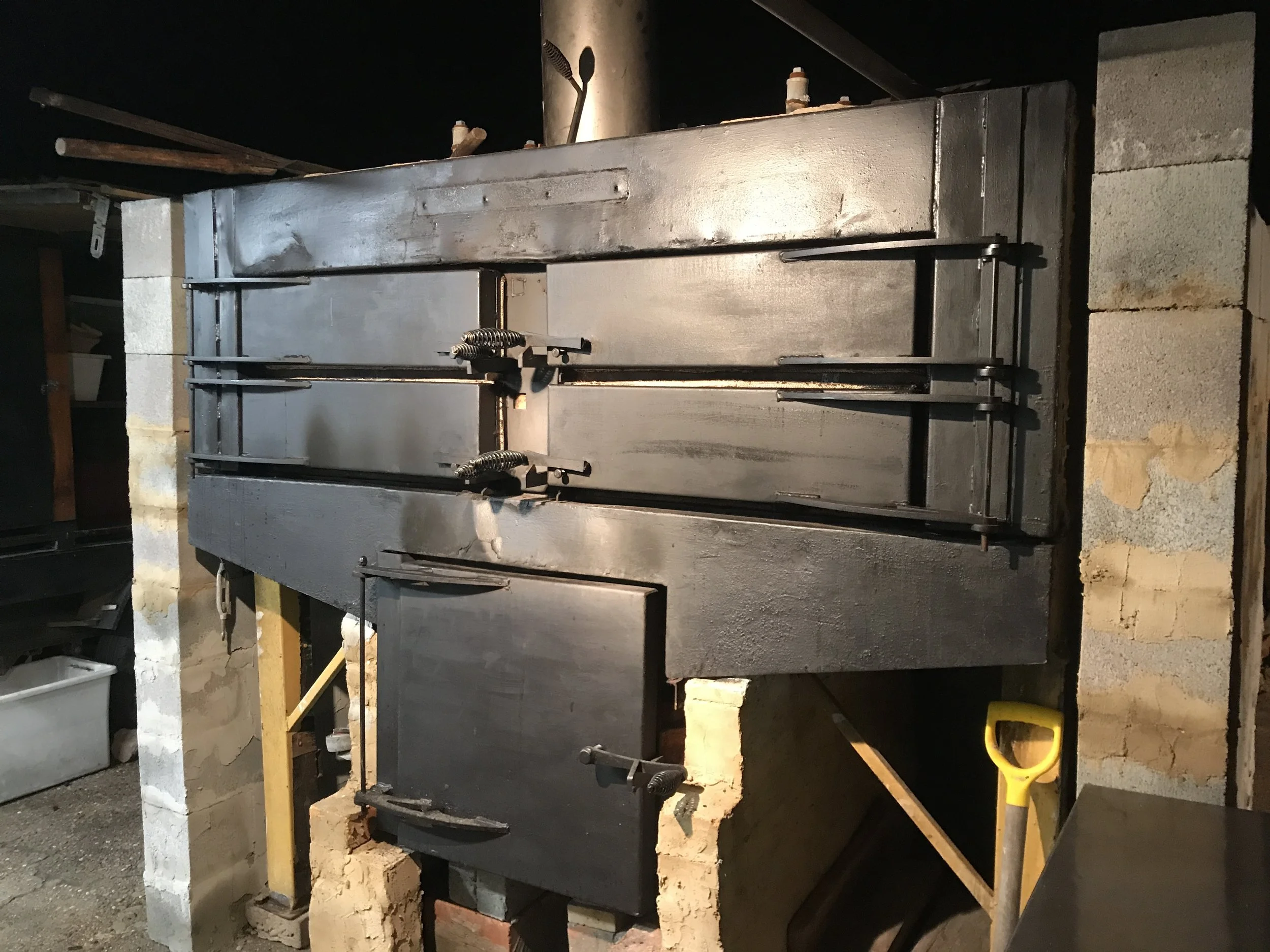

A closeup of Luna’s firebox recently after having the new V baffle fitted.

After over 7 years of use, Luna was facing yet another bout of major surgery. While this could be considered fairly routine for a well used oven, those who follow this blog will know just how much work I have put in to keeping Luna functioning.

After only a year of use since refitting her with a new steel baffle, the same baffle was completely destroyed by heat. This was a 10 mm thick piece of steel which my boilermaker advisor and collaborator assured me would do the job (at least for a few years) instead of going the whole hog and putting in stainless . Cost is always a factor in these decisions, and our judgement call wasn’t the right one. I expected it to last for at least a few years, as I was only using the oven for a day or two each week. But I watched that baffle gradually burn out over the past couple of months, working around it as best as I could for that time, and found myself thinking deeply about my history with every oven me and the boilermaker have ever created this last 12 years or so.

Bertha II and her firebox repairs. Big firebox, and a bugger of a job!

Berth 1, Bertha 2, and Luna, being the names I’ve given to three woodfired ovens I have had a direct and long term association with, have all caused me lots of physical and financial pain. I have crawled inside each of them, as well as other ovens made with our template - in a couple of cases while they were fully hot - and it’s never a pleasant (or healthy) experience. While all of them, after much post production work, have functioned well in the end, they each have had massive problems. These problems usually stemmed from the fact that metal degrades and warps over time, or is simply a very unforgiving material to work with.

Thus, I decided to avoid the material as much as possible in all my future ovens. I’m totally done with the complexity and cost associated with ovens which are essentially using lots of metal to hold masonry in place. Woodfired ovens have been made for centuries successfully with just brick and mortar. Why reinvent the wheel?

I’ve been working on a full masonry design for the past 12 months, and have finally built a small prototype to see how the masonry version of a ‘white oven’ will work. The design has morphed into something quite different over that time; when I look at what I’ve created I can see the original concept, but that’s about it. The way I got to the concept twisted and turned quite a bit.

The new prototype at the firebox stage.

The materials to make the oven evolved - I started with the idea of using common bricks with oven bricks used in various strategic places, which had merit; cheaply sourced common bricks can do the job, especially if you also use high temperature bricks on the parts of the oven where there is a lot of heat. But this prototype was to be built on my trailer, and I was worried they would require a lot of bracing to hold them together. Trailers bump around a lot on the road. Also, weight (at that time) was an issue, and I wasn’t sure brick was light enough.

Then I considered cast cement and AAC (Autoclaved Aerated Concrete), both of which I could cast myself. This attracted me as I could cast exactly to size; if I could cast fairly thin sheets I could save weight. I designed some molds which enabled each piece to lock into each other. The further I went down the casting rabbit hole, though, the more complex things became. The casting process seemed like a lot of fiddling, and was fraught with traps for newbies like me, so this idea morphed into using pre cast cinder blocks and manufactured AAC (Besser bricks and Hebel, being two brands commonly available locally). Off the shelf, at least in theory, it was possible to get pretty close to the correct size for the project. I tweaked the original design a little to accommodate them - then came to a road block - my design worked on an uncommon size of besser brick, being thinner than the usual construction kind. I only needed about six of them, but they were critical to the flue design in the oven. Do you think I could find anyone who would stock or sell me 6? The smallest amount I could order was a full pallet. So I went off looking for other ways to skin this cat.

I’m wandering around various landscaping and building suppliers in my new home town of Gloucester, looking for stuff to build my oven with, when I notice an unusual brick with three large holes. Immediately I see how it could work in my oven. While I wasn’t able to buy it, the retailer put me in touch with their maker - Lincoln Brickworks, just down the road at Wingham.

A quick drive and I’m chatting to the brickmaker himself. Before long he’s showing me their kilns - which coincidentally are wood fired till they get to 700C, then oil fired to take them up to 1300C. Lincoln bricks are one of the last independent brickmakers on the eastern side of the country - and they make their bricks in small batches, catering to the niche of the trade interested in truly bespoke, rustic materials, and craftsman techniques from the past. I’m sold, and the brick maker helps me load up 40 of them to try for my ovens. When I go to pay, they wave me through, saying ‘you’ll be back - we’ll sort it out then!’

Brick sides are on and rendered.

The bricks were used in the final prototype, and they worked as intended. They are stacked directly on top of each other in the side walls of the oven, creating flue pipes for the flue gases to travel along. The flue pipes lead around the oven, transmitting heat from the flue gas directly to the baking chambers. This meant that the baking chambers would heat up quickly, and that I would be reducing a whole layer of brick from my design, making it lighter.

I also built the firebox out of common brick, and lined the insides with firebrick. For a baffle above the firebox, I did some research into concrete, as my local hardware store sold 600 x 600 (2 foot x 2foot) slabs which were about 100mm thick. This was about the right size for the base of the baking chamber, and would save me a whole lot of time and expense with fabricating some sort of lintel to support a brick baffle. This was my first major error.

Then, bang! The concrete baffle exploded!

According to everything I read, concrete could withstand 600C heat. From experience, the internal temps in all my previous fireboxes reached 500C, so I figured I had a bit of wriggle room. I was very wrong. On the first trial firing, maybe half an hour in, I heard a large deep ‘boom’. I checked the baking chamber, and a hole had blown right through the concrete! So much for 600 C! It’s possible the slab I had purchased was not adequately cured - because I had taken temperatures inside the firebox some 5 minutes earlier and it had barely reached 200C at that stage. Far too low, I would have thought, to cause the concrete to react with the heat. Despite this fairly intense reaction, the oven held together.

I visited our local ‘Tip Shop’ (a most wonderful community resource where waste is sorted, displayed and sold for super cheap) and found some really heavy duty BBQ plate steel. I was able to support this underneath the slab, and thereby create a secondary level of baffle. I then used a high temp mortar mix to fill the hole in the slab, and put 30mm oven bricks on the top.

Shelves are added and bricks used in place of a firebox door.

Thankfully, this very quick and cheap repair meant that I could use the oven. I had quite a few subscribers to my bread delivery service (see previous post on my CSB) who, having not received bread during the entire period of relocation and oven building, were starting to lose their minds. I didn’t want to lose them as customers, or to have them lose their minds due to bread starvation, so I was in a hurry to get the prototype fired up and baking.

Over the next 6 bakes or so, I grew quite fond of my prototype tiny oven. It was relatively quick - 15 loaves an hour vs 20 per hour in Luna, which was 4 times the size. It was fast to heat up too - from cold to bake temperature in 2 to 3 hours. It also gave a wonderful kick to the loaves - my original spacing between the shelves was now too small, as the loaves were bigger than they were before by approx an inch! The prototype worked better than I thought it would, and really didn’t require a whole lot of modification, beyond repairing dodgy little bits of my super low budget repurposed construction materials.

But there were some problems. The primary issues were:

A baking chamber door is attached. It opens to a flat 90 degree platform.

getting the door to seal correctly. Smoke from the firebox would creep in under the baking chamber door and taint the bread. The door was a piece of fairly thin steel from a previous oven which had been used as a shelf. The seal between it and the masonry was less than perfect, so I used some ceramic rope and high temperature tape to bog up the gap. It worked, after a couple of less than satisfactory attempts.

creating steam in the baking chambers. Due to my lack of welding equipment (and the lack of welding knowledge) I struggled to fabricate a way of holding water in a piece of pipe. The pipe system has been used successfully in all my previous ovens, but they required a welder to make them. This time I was in a new town and I didn’t know anyone here. Eventually I purchased some rectangular hollow galvanized bar and filled the ends with cement to block them off. Then I cut some grooves along their length with an angle grinder, which allowed steam to escape. They worked extremely well. They held close to a litre of water, which provided enough live, gentle steam to the baking chambers for some 15 minutes at a time.

properly insulating the surrounds of the oven. I built the oven to fit into the existing space on my trailer. There had been a small oven there previously which I used for demonstration bakes and workshops. To save time, I simply beefed up the existing insulation around the wall area and re-did the roof insulation. The floor had a layer of insulation too, as well as a sheet of rubber to isolate vibration from the oven. The oven base was 100 mm hebel, which is, in itself, insulation. The outer shell was made of this also. I figured I had it all covered.

I did not. After the first couple of production bakes, I observed smoke around the top of the oven. This worried me, so I removed the entire roof and replaced it with brick and corrugated iron. So much for weight! I could no longer tow the oven, but at this point I was quite happy for the oven to be semi permanently set up at my new home base in Gloucester.

Fired up for the first time!

After another couple of bakes, I noticed smoke coming out from UNDER the oven. While the top was now fine, smoke coming from under the oven really confused me. There was so much insulation and brickwork around the firebox, it just didn’t make sense. I added another layer of brick to the base of the firebox and the problem seemed to go away. Or it became less obvious, as I now know!

Needless to say, I was inspired by my little protoype. However, I could see that my construction techniques were not up for the long haul, and that I would need to be doing a lot of spot repairs to keep the little oven alive until I could make a bigger, more robust one.

Last week, after finishing the bake in record time, I felt I had mastered the oven, and made all the necessary tweaks for performance I would need to do for a while. I went to bed early and was keen to get the bread delivered the following day. A good bake is a wonderful thing for the psyche.

An early test run alerted me to the need to rebuild the chimney!

I woke to a loud ‘boom’ at about 2.30 am. I could see flickering light through the curtains, and stepped out to find the trailer and a couch in the undercover garden area fully blazing. As I ran to grab the hose, a second couch exploded into flame - I had put them perhaps 8 feet away from the other side of the trailer just two days earlier.

The fire from the trailer had engulfed them and caused the explosions. Luckily the local fire brigade came in 20 minutes or so, but those 20 minutes were I think the longest in my life, as I pointed an ineffectual hose in the general direction of the blaze. The fireys brought it under control in about half an hour. I wandered around on the footpath outside with loaves of freshly baked bread at 3 am for them as some form of thanks.

First bake!

(photo, on B+W film, courtesy of Maira Wilkie)

I lost the trailer, as well as a fair proportion of my power tools. I also lost some printing equipment, and a good deal of pride. I thought I had insulated the section around the oven well, and indeed I did. The problem was under it. I built the oven on AAC (hebel), with fire bricks on top. There was a layer of wool insulation batt under the oven, with a thick rubber matt under that, and foam under that, and finally the timber frame built on the trailer years earlier. The weight of the oven had slowly flattened the insulation, making it less effective. The heat from the firebox had found its way through all the insulation, and had created a smouldering heat issue which had slowly, over quite a few weeks, degraded the timber framework underneath. This simply gave way, the oven tilted backwards, and hot coal spilt out of the firebox, setting the whole trailer alight.

Disaster! Half a dozen bakes later, the fireproofing under the oven fails, and the oven tips over, catching the trailer on fire and destroying it completely.

Apart from feeling stupid at my errors of construction, I felt defeated. It’s taken me 30 years to be at a comfortable place with my craft. I get to bake commercially just once a week, with civilised hours. I have many happy subscribers to my bread delivery service, which has continued each week now for two years or so. I try to impart good info to anyone who wants to know. I’m deeply immersed in my craft, as anyone who has spoken to me will be quick to agree. Many 300 series students have gone on to start their own successful micro bakeries, as a result of my inspiration and guidance.

Over the years, thousands of home bakers have come to learn at my 101 workshops held each month, and many stay in touch, attending numerous workshops to keep their bread making processes improving and growing . I’m deeply happy to be part of the bread making renaissance in Australia. When I began, bakeries were heading away from natural bread; there was not an interest in using organically grown grain or in artisan milling or fermented bread at all. Now there are hundreds of successful bakeries turning out great bread all around Australia, and when I speak to them they are rightfully proud of their product. There are a number of mills creating superb, sustainably grown flour from quality grain. Of all this, I can say I was one of many who worked to make it happen.

The bakery business has been tough on me, and my body. I’ve earned a living though, and I’ve largely been my own boss for a long, long time. I’m rich in what I know, and I’ve been further enriched by the responses people have to my bread, my teaching and my professional guidance over many years. I’m not materially rich, though - I discovered some time ago that I have little interest in material gain beyond what I need to keep going. This I know is both a problem, and a solution to bigger problems.

Thus I find myself questioning whether I should go on; to rebuild, or to find another way of earning a living. I feel like I have been a professional crash test dummy for too long. It’s my own doing, I know. And I do question my sanity from time to time.

In Western Australia teaching Bush Baking a couple of years back, with the trailer on its second incarnation.

So I’m asking you, dear reader, to really help. I have decided to seek contributions to a crowd funding initiative, to help me build a new oven and to rebuild the site, so that I can get the School of Sourdough properly established here in Gloucester. I need to buy materials to build the oven, as well as some new tools and some professional assistance so that the new setup won’t have any issues down the track. If you think I should continue doing what I do, then follow the link below and make a contribution. If I can raise $20K I’ll be over the moon. If I can raise half that, I will still be able to get things up and running again. Any amount will encourage me to continue. Even nice words and a bit of virality by sharing this post will go a long way.

People who can contribute will be rewarded in any way I can - small contributions will get free bread to equal value when the oven is finished - provided you are somewhere in the Hunter Valley region. Bigger ones can receive one on one tuition/consultation to the value of their contribution down the track, here at the bakery or over the phone, if necessary. Really big ones will receive eternal gratitude and whatever else I can give to say thank you. And everyone will be supporting a community enterprise as well as a journeyman baker who needs to know if he’s mad or not. Please chip in and help me get this project finished!

The Community Supported Bakery a year on

It’s been just over a year since I began baking purely for subscribers here in the Newcastle region of NSW. Before that, I focused on local markets as my retail, but after six years of doing this, I found that in our region market operators have become very risk averse. They increasingly would cancel the market at the first hint of rain or wind. Not great for the local baker who has a day to sell their bread.

It’s my second attempt at creating a Community Supported Bakery - my first was a few years back when we set up the bakery out the back of Wesley Mission in Newcastle West. We were delivering bread every Saturday all over Newcastle, and while it worked quite well, the retail business and Cafe we built on the Wesley site took over.

I learned from our experience in supplying people directly that the subscription baking model needed a few tweaks for it to work long term. This time around, after building the model around Pick Up Points (PUPs) rather than home delivery, I believe we’ve got it close to right. I’ve approached a number of strategically located businesses, whether they are retailers or cafe operators, and offered them the opportunity to become part of our Community Supported Bakery network as Pick Up Points for our subscribers. This provides the subscriber, the PUP and the bakery with positive benefits. The bakery gets a retail location for bread. The subscriber gets a convenient place to pick up their bread, and the PUP gets added foot traffic to their shop or cafe.

The baby oven I used to bake my way across Oz became the CSB’s first baking tool.

When I began baking for subscribers again a bit over a year ago, I was using the Bush Bakery MkII for the task of baking maybe a dozen loaves every Friday night here at the farm. My proper bakery, here in the old dairy shed, wasn’t built, so I was living in my caravan, trying to keep things afloat. The Bush Bakery MkII would have to do while I was waiting. It was less than perfect, and the bread I was baking from it was also less than perfect. But I pushed on anyway. Thankfully, my customers were patient.

I was hankering to bake great bread again in Luna, my main flame. She was still in pieces out the back shed as Craig Miller was refurbishing her in his spare time. I had to play the long game if I wanted to have her baking again.

Not easy for me. I always want things finished asap so I can get on with other stuff. Everything seemed to be in permanent slomo. I was going crazy. My weekly bake in my little baking trailer kept me sane.

The dough box takes shape.

At first, I was doing the whole thing completely by hand, using my ‘dough box’, which I’d recently completed, making it out of used plywood transit boards. Transit boards are what we call the plywood boards used to rest finished and shaped dough on before baking. I had plenty which were old and needed to be replaced, so I cut them up and created my dough box from them.

I had just returned from my trip across the country in the above mentioned trailer bakery, and I’d been using standard dough tubs to mix my dough by hand for the trip. The idea was to make the dough box before I left, but I ran out of time. As soon as I got back, I set to work on it, and it was finally finished. I made it waterproof and super smooth, and began making dough in it. I found that it worked pretty well for 10kg of dough - in fact, it was surprisingly efficient.

The Community Supported Bakery (CSB)

A Community Supported Bakery can take many different forms. In some places, bakeries are set up to meet community demands - and thus are entirely funded by these communities. Bakery entrepreneurs have used crowd funding to get their dreams up and running for many years. I remember meeting a baker from Berlin who had done this some 20 years ago, simply by putting handbills on the walls of cafes to gather support from the community. In other places, customers and staff are members of a cooperative. I attempted this idea a decade ago in Newcastle and failed miserably. I have seen it working though, and while the environment for a cooperatively run bakery might not be here in Australia (with a raft of incorporation laws which make forming a coop very expensive to do, and then also expensive to run when it’s finally set up) , the idea has a lot of merit and could work in places where there aren’t such onerous laws. I’d be very interested to hear from anyone who HAS managed to get a cooperatively run bakery up and going here in Australia though!

There are lots of other ways for a bakery to be supported by the community. Turns out, communities like to have bakeries which are run by people rather than corporations.

There are CSBs which simply have a membership system, with members helping to finance the bakery’s operations each year by their membership fees. In return, members get first dibs at the bakery product, often for a discounted price. Other CSBs go for a share system, where the investors receive a dividend when the bakery becomes profitable. Still others tag on the back of established buying groups, enabling them to bake directly for buying group customers.

This incarnation of my CSB is supported by a subscription system. It’s a way of supplying customers over the long term with affordable, nutritious bread. Users of the system get discount bread by committing to a number of loaves which they can have delivered, one at a time if they like, over an endless time frame. The more loaves they commit to, the better the price per loaf. Bulk buying without the bulk, if you like.

It’s like a phone card - they just top up their credit when they need to, and receive supply whenever they want. Better prices are also available when a customer orders a number of loaves at the same time. This means that a reseller can be part of the system too. Bread can then be purchased by anyone at a standard retail price without actually having to subscribe by simply popping in to one of the resellers and buying it over the counter.

The subscription system can be tweaked to be time based, which encourages regular use. Ours isn’t done that way here, because in Newcastle, at least, people want maximum flexibility. It’s a tough market! Nonetheless, our subscriber base has steadily grown over the year, and we seem to be holding on to our customers.

Our CSB so far

So a dozen loaves, paid for in advance by members of the community, was the start of it. Now we are baking about 85 loaves each time I fire up Luna the oven. We have an ‘apprentice’ who is learning the trade from the ground up, and students regularly attend our bake day workshops so they can learn how it all fits together.

Over the coming couple of months, we’ll produce a hundred loaves per bake. At that time, I’ll consider firing Luna up a second day each week - once I’ve found someone who can distribute them more widely. Eventually she’ll get fired up more days, one day at a time. The whole idea is resource management - so when the oven’s five or six tonnes of thermal mass gets fully soaked with heat, she becomes much more efficient. I just have to find homes for all the bread!

Do you know someone who would like to distribute the bread more widely, so that we can fire up Luna more often? Leave a comment after the article and I’ll be in touch!

In the meantime, our bakery is settled into a steady rhythm. We have students visiting throughout the week to learn or revise what they have learnt. Tuesdays we make sponges for dough. Wednesdays we make the dough. Thursdays we de-gas the dough we’ve made for the first time, and prepare firewood for the bake. It’s a 72 hour process from start to finish, and it makes the bread really digestible and full flavoured.

Here on the farm there is a pretty good supply of wood, but there’s always the process of trimming the wood we have to fit Luna’s firebox. This happens on Thursdays. It’s also a good day for weeding our small garden, produce from which eventually becomes jars of pickles and pastes for our family, friends and subscribers. It’s also the day I do oven maintenance - Luna gets a deck and firebox clean, as well as a blow out to clear her flue system of all soot.

Friday is bake day, and we start by cutting and shaping all our dough, ready for the final proof. Luna is fired up in the morning, and we keep her going until baking time begins in the late afternoon and early evening. By this time Luna is steady at about 220C. When we have good fuel, it’s a matter of holding her down to temp; when it’s not good, it’s a matter of cranking the firebox along until the decks get hot enough to bake. Baking currently takes between 2 and 4 hours. Then we let the bread cool on racks, and pack it for delivery Saturday morning.

Saturday is delivery day, and I head off to our 5 Pick Up Points to deliver the bread early in the morning. Deliveries are all done by 10am. Then we rest, ready to do it again next week!

One or two Sundays each month are dedicated to teaching the general public, with 101 and 102 Workshops held. It gives people a chance to learn about proper bread as well as to have a look at what we do here.

It’s a comfortable rhythm to live with, and allows time for things like gardening, administration of our subscriber system (which takes a good few hours each week), essential maintenance of the bakery and oven, and development of the site here at the old dairy shed.

Once we start baking twice a week I can see the time becoming tighter, but there is still quite a bit of capacity time wise; the routine here somehow allows for extra stuff without too much stress.

If you would like to see how things work in our Community Supported Bakery, why not book in and learn about the process for yourself or for your group? You can bring along as many as 6 people for the one price.

The Rebirth of Luna

Luna’s been rebirthing. You’d think she would have learned!

Luna’s about 7 years old. For an oven built as a prototype, that’s getting on. She’s had a robust, quite eventful life so far. She’s lived in four locations, as well as a short stint living ‘on the road’, as the centrepiece to my first travelling bakery and classroom. She was designed to be a mobile, high volume wood fired oven. She was meant to be light, heat up quickly, and be able to bake 300 or more perfect loaves of bread in the space of a market - which would be around eight hours.

For this task, she was a complete failure. The entire mobile bakery enterprise had a number of flaws, as it turned out. I may well have covered these, and the mobile bakery, in a previous blog post; I can’t remember. Anyway, that’s not what this post is about.

That’s Luna’s bush hideaway. She’s in the box…

Luna found her place as a stationary oven. She lived on a fixed site, still on the mobile bakery trailer, at a bush hideaway in Ellalong, where she performed the weekly baking duties for local Saturday markets with incredible finesse. I knew the difference Luna made - a kind of crust that only a brick oven can give you.

She was always a bit tricky to work with - she liked to be pre heated for a good 5 hours before she would really begin to sing, for example. She had some hot spots (which became completely ‘worked around’, as one does with any old bakery oven), and she needed a major clean out and overhaul every year, or she would block up (and actually melt) in parts. I had to rebuild the firebox a couple of times, and used a crowbar to open up a pathway for flue gases when it fatigued after about 5 years use.

I learned the hard way with Luna, every time, but after each rebuild she returned to work, better than ever. She was, for many years, a ‘work in progress’. She eventually became an excellent oven, capable of baking an average of 30 average sized full sourdogh loaves an hour - provided I was on my game - and more if someone was helping me. She did her job as a test bed and we improved our Aromatic Embers ovens as a result.

When the first Bush Bakery at Ellalong came to an end, I packed Luna up in the trailer, took out her bricks, and parked her in a nearby paddock, where she lived for a few months. I towed her here to the farm, and she was parked again for a few more months. We removed her from the trailer after the Tour Down South, and a boilermaker began the task of refurbishing her, with design modifications we had now applied to some of our other ovens.

Luna was my third prototype. I was the test pilot and outside design consultant. Actually, I became the crash test dummy more often than not. The first two prototypes, both named Bertha, turned out to be absolute pigs of ovens, but pigs which were made to sing for their supper nonetheless, thanks to my need to bake decent bread.

Bertha 1 in Cafe mode. Note bricked plate warmer on top!

Luna was different. We really thought about Luna - all our mistakes taught us what NOT to do. So Luna was a decent oven from the getgo - but she developed some long term issues. That’s why I was always working on her - she took a fair bit of tweaking to make her really sing, I can tell you! So when I left her in the boilermaker’s capable hands, I gave him my wish list - or at least half of it. I knew I’d be doing the other half myself.

This time I wanted to make the flame generated from the fire really stretch, so that it could do the job of heating more cleanly, quickly and efficiently. We needed to get the bottom decks more even too. Back in the day, the area above the firebox was always the hottest part of the deck. It was so hot that I had to set loaves to one side so they didn’t burn.

The boilermaker takes Luna apart with the tynes of a tractor.

Stretching the flame in Luna’s firebox.

The top decks have always relatively slow, so we set out to improve the heat here at same time.

The boilermaker built a more sophisticated and heavy duty baffle system, based on my ideas. He made the baffle itself more angled so that flame was siphoned off better when it runs against it from the firebox. I later bricked the inside of the firebox to further enhance the ‘flamethrower effect’. He rebuilt the firebox to include more brick than before. He also incorporated a whole series of cleaning access tubes to the roof of the oven, so that the area nearest the flue could be cleaned - an issue which had reared its ugly head a couple of times in Luna’s life already.

I’m hoping the changes to the flue system will eliminate the problem of soot build up altogether. I’m fully aware that I may simply be experiencing a case of wishful thinking here. Every designer wants their latest and greatest innovation to work - we always wear rose coloured glasses, to a certain extent. Sometimes, though, it pays to take out insurance. If there was still a build up of soot, despite our new modifications, at least I can now clean it out more easily than in the past.

Luna’s cleaning tubes before they get bricked and mortared.

All this work took many months. Luna was positioned in the middle of a paddock full of farm equipment. When the boilermaker was on the farm, he’d carry Luna’s bits over to the shed on the tines of the old tractor. He’d weld and angle grind and rivet for hours on end. From time to time I’d ‘lackey’ for him - just as I did when Luna was fabricated here on the farm years ago. Only then, as I remember it, I was on crutches. That’s a whole other story. Not this time - I walk pretty well these days.

More heavy duty thermal mass is added before putting Luna back together.

As the work on Luna slowly got done, a bit here and a bit there, the dairy shed also got finished - in much the same manner. A few weeks ago we carried Luna’s 2 finished pieces over to the dairy shed on the tractor, and we put her back together for the first time in a year. Then we positioned her outside the new school classroom and bakery, where she will live for quite a while, I hope.

Luna 2 showing inner layer of brickwork. This will be wrapped with besser brick.

I’ve been bricking her up, inside and out, for the past two weeks or so. It’s slow, heavy work, as a great deal of the brick is in really hard to get at places - inside baking chambers, for example. These baking chambers are only 16 cm high and a metre deep. One slides the bricks in on the end of a metal peel, and manipulates them as best as one can from a metre away. Around the baking chambers there are two layers of brick, and another layer on the top of them. Getting the bricks in place involves climbing up a ladder with brick or bricks in hand, keeping a fresh mortar on the go all the while, for maybe a couple of hundred climbs. Each brick weighs between 2 and 5 kg, and so far I’ve put roughly 500 bricks in and through and around the oven, as well as another couple of hundred inside the baffles, which we did before she was put back together. I’ve only done enough, at the time of writing this, to fire the oven up and make it work.

First layer of brickwork done. The oven is functional here, though nowhere near thermally efficient.

All this extra thermal mass and insulation will become necessary when Luna goes into production mode for the ‘Steady State Bakery’. It will operate as a heat sink, as well as a kind of heat mirror; the thick walls of brick should hold heat for days. Luna will become a super efficient oven.

i was inspired in my design for Luna by spending time at Harcourt Historic Bakery with Jodi and Dave when I did the Tour Down South last year. Their oven is capable of holding high temperatures for days after firing, as it has some 72 tonnes of brick around it. It’s an incredible piece of kit for a 100 year old oven. Dave manages to keep it hot with very little timber each day.

My version only will have maybe four or five tonnes of brick when it’s finished. The principle is similar to the oven in Harcourt though - get the brick hot, and then once it’s hot, keep it there for as long as possible. I’ll be looking for new bakery customers very soon, that’s for sure!

Next layer done. Still have to complete the outer wrapping, add more mass to the roof, and fill the besser bricks with rubble and sand.

Upon firing her up after putting her in place here, I saw that Luna was really a serious piece of flame art now. The firebox works a treat, blasting flame a good few feet each side, in sheets, spread out right under the two baking decks. It takes the oven from cold to baking temperature in just 3 hours, but will do it substantially quicker when it is fired each day or two, as it will retain a lot of heat.

Just a teensie fire here. When I fully blaze the fire, it’s too hot for my camera!

At the time of writing I’m about two thirds of the way through the brickwork. There is an ‘inner outer’ layer of brick around the baking chamber, and another around the firebox. There are two layers on top, with two more layers of grog based on mortar and recycled crushed concrete. There will be another layer of brick and mortar on top as well. There is a layer of besser brick surrounding the three sides, and I’m currently filling these with rubble, glass and sand to add thermal mass, as well as to use up everything I can from a demolished brick wall I was given. I’m going to fill a void between the inner and outer layers with insulation board.

My experience so far has been a bit different to what the world of oven builders has been telling me. One commonly held belief is that insulation like ceramic blanket or rockwool or ceramic board will ‘reflect’ heat back into the structure. While this is possible, there needs to be an outer layer of brick or thick mortar wrapping up the blanket in addition to the blanket itself for any reflection effect to occur. The blanket will eventually dissipate its stored heat in both directions - back in and out. If you wrap your blanket in brick on both sides, the blanket still fills with heat, but it slowly dissipates the stored heat back into thermal mass surrounding it. If you don’t wrap your insular material in thermal mass, you will ultimately allow 50% of the stored heat run out into the atmosphere. In addition, your insular material will actually be absorbing heat from the bricks next to it, contributing to a slower heat up of the oven itself. I learned this with Bertha 2, which took over 18 hours to heat from cold, and really only started to get useful after the second bake for the week. Needless to say, once I figured out our insulation mistake, I got to pull her apart and replace the insulation with brick, and this sped her heating time up by many hours.

The advantage of brick is that while it absorbs heat, it also reflects heat. If you sit beside a brick wall in the sun, you will experience how brick reflects heat. When it becomes ‘soaked’ with heat, it then becomes a heat source - it actually ‘radiates’. So you get reflection, absorption and dissipation (radiation) of heat, in that order. Brick, as a material to work with storing heat, becomes more efficient over time.

One uses ones loaf to make a decent loaf. Or so they say…

So far I’ve used the oven for my standard bakes, and have kept the oven warm over multiple days doing various tasks - slow roasting on one day and baking pizza on another. Luna can hold baking temperature without fire for a couple of hours at the moment. In fact, the top decks increase in temperature for the first six hours of firing, and continue to increase without fire for the next three hours. On some nights I have finished the bake and checked the baking chambers about 10 hours later, and they still held over 120 C. I think I can improve on this by a significant amount by just beefing up the thermal mass and adding strategic insulation in some places.

I’ve done the big stuff, now I will do the little things. Watch this space.

If you would like to experience Luna first hand, I run workshops for the general public each month. Professional baking workshops are held four times a year. Check out what’s on offer.

Post script:

Just a little update regarding Luna’s thermal performance. Since writing this article, I’ve filled in all the besser bricks with rubble, bits of brick and crusher dust. I’ve also enclosed a sleeve of air surrounding the baking chambers with brick. I’ve bagged the outer shell with mortar, and I’m half way through adding a layer of bottles covered in mortar over the top. Once this is done, I’ll paint the top section in black bituminous paint. At this point, the oven holds an average 100 degrees C some 12 hours after a full bake of about 80 or so loaves. It takes just a bit less than 3 hours to reach baking temperature from cold, though if I really want the oven to be fully ‘soaked’, I’ll pre heat for about 5 hours. I’m yet to gather data on how long the oven takes to heat from 100 degrees, but I think it should re heat in just a couple of hours. All the little bits I’ve done to make it hold heat longer are making a difference; and I can see I’ll be doing more as the need to use the oven more often grows with demand for bread. I’m also noticing that to heat the oven takes less fuel now. This is a bit unscientific, because I’m using different wood from around the farm, but the effect is still noticeable. I still don’t have enough demand to fill 2 days baking, but this will gradually build as I get out and gather more subscribers.

The birth of ANOTHER bakery - among other things.

The foothills of the Great Divide

Crossing the country and having this past year as a ‘sabbatical’ from baking commercially has led me to a number of realisations. The whole time, I’ve baked for myself and my students; I’ve had good bread to eat. Since I returned, though, something has been missing.

I’m addicted to my bread.

Addicted to bakeries?

Lets face it. I’m addicted to baking, and I’m especially addicted to my bread.

This extends into building actual bakeries so that I can make lots of the bread I really like to bake.

Like all addictions, it is multi leveled.

Firstly, I need to eat this bread. It’s like my medicine as well as food. As long as I have this bread to eat, the world, in my eyes, is okay. Even if I have very little money, I have nutrition - all I require is a piece of bread, maybe some cheese and tomato, and I am nourished. Other breads just don’t do it for me in the way mine does. Not to say there aren’t other great breads - it’s just that I’ve arrived at a very specific bread and I would like to keep having it for breakfast. And lunch, if possible. Occasionally dinner is okay as well.

Then, the addiction to the process of baking it kicks in. Baking provides a weekly rhythm, something to structure your day around. The process is its own reward - a good bake, and you are on top of the world. Of course, a bad one is somewhat less than ideal, and a number of bad ones in a row can be soul destroying. Luckily, there are more good bakes than bad ones.

Finally, the addiction to the financial reward can’t be ignored. When I bake each week, even just 30 loaves or so, there is cashflow. When you are a micro business, regular cashflow is everything. Before I moved from Ellalong, I was baking a few hundred loaves at a time, and this provided the bulk of my regular income. Now the weekly bake makes up a small but important part; teaching, consulting and training make up the rest.

Oh for a ‘Steady State’…and I don’t mean politics!

Some ideas pass naturally, while others persist - or more correctly they mutate in my mind.

I’ve been in the food business now for over 30 years - and for the past 29 I’ve been involved with bakeries and cafes. I’ve been wondering about energy use that whole time. I’ve experienced, lamented and deeply pondered food waste. Another issue to fill my grey matter has been wear and tear on bakery equipment.

After a while these three categories of problem morphed into a single simple solution. I want to establish what I call a ‘steady state bakery’. The idea is a bakery which produces the same basic amount every day. It doesn’t grade up production on one day to wind it down on others. It won’t be ‘market driven’ - like most bakeries are, as they surf the highs and lows of bakery production life.

I’ve written about this subject in earlier blog posts right here. Scroll backward and you’ll pick up multiple references.

All machines, and I’m including a bakery as a machine, are designed for optimal conditions of use. Then they are tweaked to extend the conditions to make them operate in real world conditions. When a machine is dynamic, it wears out more quickly.

A stable machine wears less, and consumes less energy. When a machine operates at the same pace all the time, stresses and strains are minimised on the componentry. They last longer and consume less energy.

Humans are different. They don’t mind work, but they need rest. And they need rhythm. Humans do well with a combination of routine and rest. Any human centered machine has to factor in humans.

My past two production setups have been specifically designed to supply weekend markets. This means that they bake large volumes on just one or two days a week. The rest of the time, they are either dormant, or being used for teaching, consulting or pre production work. So each week the machine gets wound up, stretched beyond capacity, and then wound down again.

A baker commits to the market each week, whether it is on or not. They work days in advance as they go about their routine, and by market day they are simply loading their freshly baked bread into their vans to meet their customers and to get paid for their work. If it rains and the market is cancelled; their payday just disappears. Then, the word wastage takes on a whole new meaning!

Every bakery has a lot of production variables; the seasons, new customers, wholesale business orders, local trading conditions, bakery competition, weekend markets and much more. Thus, all these variables inevitably lead to bread waste, and volatility.

A bakery, then, is usually a highly dynamic machine. Dynamic machines are prone to failure.

The ‘steady state’ bakery is different; it’s meant to produce the same amount of bread each bake - each day, week or month. It’s a machine with a daily rhythm based around repetition. It’s designed for a particular volume - nothing more. It doesn’t get ‘pushed’.

By doing this, there are many benefits. The machine doesn’t have to work hard - it just works the same amount each time to get the job done. Thus, the machine lasts longer and uses less energy. The more often it works, the less energy it requires in proportion to the output. The machine can be scaled up or down according to requirements, but in a planned way.

With a daily and weekly rhythm in a Steady State Bakery (SSB), there is a curious bi product; learning happens through repetition. The bake is a series of processes which are done at specific times, each with its own set of KPI. The only person who needs an overview is the baker. Through working with the processes, helpers gradually understand the overview; through learning all of the processes involved in a hands on way, humans involved piece together the whole picture, little by little. So a SSB is also a great environment for learning processes.

Another advantage of an SSB is being able to properly plan for the bakery’s resource use. Things like fuel, ingredient supply and freight all are best delivered in steady amounts, not only from the bakery’s perspective, but also from a logistics point of view.

Still another benefit is to be able to concentrate on reducing the environmental damage which a bakery can create. A SSB makes it easier to have a cause and effect solution put in place as there are no extremities to take into account.

Subscription baking - bread as a service

Every baker loves to set production levels to suit ourselves and our equipment. These levels should also enable us to make a crust. (:))

We have to find homes for all that bread we are baking - we definitely don’t want waste. As mentioned earlier, supplying markets leads to waste, one way or another.

To achieve steady production and sale of bread, with as close as possible to zero waste, I decided to set up a subscription system. Customers ‘subscribe’ to my baking and delivery service. By purchasing multiple loaves in advance, subscribers save money. They are bulk buying, with the convenience of having just a loaf or two delivered when they want it.

The bakery gets the benefit of steady customers and cash flow every week. And ‘planned by demand’ baking, so that only the amount ordered is supplied. The bakery works by the batch, the size of which is determined by the number of subscribers at any given time. There is always a degree of guesswork in determining the batch size each week, but the risk of wastage is reduced dramatically when compared to baking for a market which could be cancelled at the last minute.

My first attempt at subscription baking was about 8 years ago when the bakery was in Newcastle West. The model worked really well, but I moved into opening that bakery for retail business, and just outgrew the subscription model.

This time, the plan is to stick with subscriber based retail and incorporate it into the fabric of the School of Sourdough. A Steady State Bakery which is also a school, driven by subscribers.

In a bit of a departure from the original plan, I’ve included the possibility of resellers or ‘value adders’ being able to access the service. This means if you have a cafe or a shop or a food co-op, you can also subscribe. At the time of writing, we have two retail outlets on board, allowing the general public to buy bread on a whim. There is space in the system for more businesses to subscribe to the service, so those of you who want next level bread locally can get it without actually subscribing - all you need to do is to convince your local cafe or health food store to subscribe for you!

I’ll go into the new range of services in a separate blog post very soon. If you’re interested in becoming one of our Newcastle and Hunter Valley region subscribers, here’s the link!

Cicadas ate my bellbirds!

It's mid summer here in the Watagans. I can barely hear myself under the din of cicadas. It's so loud that it causes the internal cavities inside my ear to rattle when I go outside.

Right now, there are literally millions of cicadas surrounding my house. I know this, because they are all churping at full throttle as I write. The sound comes in waves, reaching a deafening crescendo before subsiding somewhat, but without end. All day long. Inside the house, it's bearable if I close all the windows, turn on the air conditioning, and do something noisy. Unfortunately, it's really difficult to listen to music, as the pitch of the cicadas removes a certain frequency from one's hearing, like white noise does. Right now it's early morning and not so hot, so I have all the windows open, and fresh air is flooding through the house. Accompanying the din, there is nothing. Most of the birds have vacated - I think that's what the cicadas are doing, by singing at the top of their lungs - they are driving away potential predators while they emerge, mate, lay their eggs and die. Even the dogs have fled to escape the noise. My pack of canine cuties essentially follow me around wherever I am, so if I'm in the house, they are on the verandah. But not today. They are hiding in the cavernous garage with the door half closed to give them a break from the noise. Dogs are such ear driven creatures. It freaks them out when they can't hear properly.

For those of you who have not yet attended a workshop here, the house is surrounded on three sides by dense bush - eucalypt forest, broadly speaking, with quite a steep rise behind us. The rise leads up to an access road, which verges this place. To get up there through the bush almost involves climbing gear, it's so steep. This eucalypt scrub/forest goes on in some directions literally for fifty or more kilometres, as you enter the Watagan mountain wilderness. There aren't too many people up behind us - I would estimate maybe a dozen cars regularly use the access road - and some of them you wouldn't see more than a couple of times a year. It's the first time since I've had the bush bakery here - which is about three and a half years now - that there has been such a cicada onslaught. Pretty sure there have been some cicadas each year, but nothing beyond curiosity was aroused in me. Certainly nothing to remember. I definitely remember the super hot weeks (average 45C for three weeks straight last year), the super wet ones (a couple of years back the rains were so heavy we had to dig trenches around the house so the holding dam wouldn't flood), the super dry and hot ones (last year, again, there were bushfires on the horizon or closer pretty much every day). This place, in a nutshell, seems to attract extremes of climate/environmental conditions. Today, as it has been all summer so far, is no exception.

The bush bakery, of course, is an outdoor affair. It's pretty much a lean-to, pitched on the end of a trailer/bake off unit unit. The bake off unit has a 3 tonne wood fired oven, a tray chiller, a proofer, a make up bench, sinks and dumpout racks. It's open on one side, and has an insulated roof, with your classic corrugated iron deflector above it, installed later to provide a couple of hours' longer protection from the heat when working in 'the box', as I like to call it. It also has a stainless water tank on the roof for its own self contained plumbing system.

I've designed it for a few reasons, which I've discussed in other blog posts (have a look at sourdoughbaker.com.au for the full story about the trailer). Since parking it in its current position, I have made it a more permanent affair, attaching a demountable roof beside it, and a floor built from recycled pallet racking. I've built a very lightweight kitchen around my dough mixer, with shade mesh sides for maximum ventilation. The classroom is beside this, with mesh surrounding a large gazebo. There are blackboards everywhere, and a couple of work benches.

It's been used for baking, consulting and teaching, this space. In the main, it has been an experiment, with an aim of discovering just how little you need to make a few hundred loaves of bread. I think, to that end, it has achieved its purpose. Essentially, you don't need much at all. Indeed, at a future incarnation, I would very much like to strip things down even more. However, there are consequences in choosing to do this. One of them, as has been pointed out at the start of this post, is that for six to eight weeks a year, we are pretty much out of business. It's hard, nigh on impossible, to run a bake in mid summer. The temperatures inside the baking box get up to 50 degrees or more on pretty much every surface - this video is an example of this - and at those temperatures, dough, no matter how cold you keep it - melts. Then, when it rains heavily, you are likely to lose power as the lines gradually become saturated. Over the years I've been able to resolve power issues quite quickly, but when you have over fifty metres to travel to the nearest junction box down the side of a rocky mountain, well, short of investing large amounts of cash, you just constantly try to improve your setup. It's always a work in progress, to put it simply.

So now, in my off season, I get to reassess. It's definitely time to consider this outdoor bakery business. Those of you who have met me at a market or at a workshop know that baking is in my blood. It's very deep in, particularly in recent years when wood fired, third world simple, outdoor sessions were involved. I've been loving it. Right down to my bones.

There's the issue right there. My bones. Over the years, I've managed to stop a couple of cars using mostly my body as the initial deflector. I can tell you, it hurts like hell and I wouldn't advise it. Trouble is, while at the time you don't feel much, the ensuing years and decades make up for it - we are talking, especially, when there has been a considerable amount of time spent on one's feet - as is typical when you embark on baking off a few hundred loaves in a woodfired oven.

The process of pain management these days involves drinking warm water and movement, mainly - but I've used various substances over the years, and somehow one becomes blase about it all. I tend to keep doing the same old thing anyway. I mean, after some of the huge bakes I've done up here at the bush bakery, I'm pretty much incapable of walking more than about ten steps at a time the next day. At times, I've been able to work my way through these periods of extreme pain and stiffness, but as I get older I can see I'll need to really do some proper work on my own body, rather than on my bakery all the time.

So this coming year, I've decided to make some changes. Broadly speaking, I'll be teaching and writing and consulting more, but baking less. I can feel your pain as you discover that there will be less bread around for a while. But hear me out. In the medium term, when I've finished some infrastructural changes (which involve moving the bakery to a more hospitable environment), my aim is to establish a permanent teaching facility which can operate year round. In addition, my new full time school will bake small amounts more regularly, thereby making better use of the resources I have while not destroying my body too much more than necessary.

The idea is to have a bake each week, which students (particularly 300 series students) can run, under supervision at first, until eventually a complete student run bakery emerges. The facility will be used to manufacture a variety of products, with a semi constant production run.

In running the 300 Series workshops, I've become aware of the need for a practical facility where students can hone their skills while they are developing their individual business plan. In many cases, students are at the very beginning phase of their dream bakery, so it is often some years before their own situation evolves sufficiently to be commercially viable for them to fully dive in. The School of Sourdough can provide a venue for their professional development. At the same time, the facility can be a regular bakery, in that a small product range of great breads and cakes can be baked onsite each week for distribution and sale locally.

As far as I am aware, no such facility exists here in Australia. As yet, I have not tied down a suitable venue, though there are a few possibilities which I am chewing over. I want to remain here in the Hunter Valley, as its proximity to Newcastle, the airport, the relative proximity to both the Central Coast and Sydney make the lower Hunter ideal for this purpose. In addition, accommodation here in the Hunter Valley is both plentiful and cheap during the mid week, which is when the production run will take place.

I have already been discussing my vision with a couple of local operators in the accommodation business, but I foresee a need for medium term, budget priced, self contained accommodation for visitors - particularly close by the School, so that students can get around without car hire costs. At this point, I'm focusing on Cessnock and surrounding villages. I feel this town is ripe for something like this, and I'm very open to ideas people might have to make it all happen.

Post Script: It’s a year or so after I wrote this blog post. Since then, I’ve crossed the country and back with my Tour Down South, a traveling sourdough workshop on a specially built, recycled trailer which I tagged The Bush Bakery MkII. I’ve packed up the house/ bakery/ school at Ellalong, and I’ve relocated to a mate’s farm at Wallarobba, about an hour from there. I have begun setting up my school and bakery in a disused dairy shed here. It’s about 3/4 finished as I write this, and in a few weeks I’ll be running my first workshop from this new setup. It’s taken a while to get things done, as we are all just doing the renovations to the dairy in between other jobs. But it will be the School of Sourdough’s permanent home, and I would love to show it off to you! More details about the new bakery in another blog post soon, but if you would like to attend any upcoming workshop, you can follow this link to book.

School is in!

Welcome to the School of Sourdough!

Making natural bread has been my life's work. I've been committed to it for three decades now. I didn't go to bread school, or even do an apprenticeship. For what I wanted to do, at that time, there was no school. I didn't miraculously discover that I was born to be a baker, or to be in the kitchen at all, for that matter.

I became a baker to answer needs. Needs led to kneading, and the rest is the story I intend to tell through this school I've set up.

The School of Sourdough is, in a way, the legacy of a life spent making bread. I can confidently say that over these thirty years, I have made pretty much every mistake it's possible to make in the name of making great bread. If it's possible to get it wrong in any way at all, I have probably done it - and usually more than once. I am a living crash test dummy for what not to do in the bakery, and indeed in the bakery business.

Which is why you need to be here. I want everyone to be happy with their lot, in general. So if for some reason you choose to make natural bread, I'm here to help. Otherwise, you stand a very real chance of hurting your soul, through the endless process of failure. You don't want that. Your soul needs to sing, and when you get the sourdough process right, it certainly does this - particularly if you also choose to bake with natural fire, like I do.

If you are here due to the natural process of internet rabbit holes, I congratulate you in getting this far. If this rabbit hole has passed through some of my territory, for example my long time website sourdoughbaker.com.au, then you will be familiar with some of the content I have tried to offer. Never before in history has there been so much information available to us, and yet, despite the best efforts of Sergey Brin and Larry Page, aka; the founders of Google, we remain forever unenlightened. So many people come to my website, and my workshops, completely and utterly confused. I used to spend quite a bit of time trying to answer their numerous confusions, but these days I just work through my process of making sourdough bread with them, and eventually they begin to understand. All the guff they have been endlessly absorbing via innumerable sources gradually falls into place through the kind of understanding I teach here at the School of Sourdough. I'm more interested in helping students to understand 'why to' rather than 'how to'.

Life is short. I could spend days and years learning, and then documenting, what I have learnt to you. I could travel the world, shopping for this or that authentic method, and faithfully report my findings so that you could make intelligent decisions, based on your own judgements and quite possibly prejudices. In this way, you could try various different techniques, and safely and dispassionately assess them, according to my learned recommendations.

Unfortunately, I don't have the years for this. Nor am I a proper journalist. I am a baker, as well as a perennial student. I have been able to refine my technique, over many incarnations, to be very flexible and indeed useable from a variety of perspectives. The methods I instruct, from experience, work well. My techniques are quite different to many, but because they have been developed over many years in a fairly scientific fashion, they tend to stand up to pretty rigorous analysis. At the School of Sourdough, you can be certain you are starting from a solid base. Experience.

If you like what you see on these pages, or in my various social media feeds, why not come to a real, live workshop? You’ll get to see, smell, feel and taste the processes involved with true sourdough bread making. You might end up joining some dots from the various snippets of information you have already picked up from the internet, and in the end it may all make sense to you. If you’ve read this far, here’s a link to guide you to more. There’s all the current workshops there, as well as sourdough starter for sale, and various other bits and pieces. Enjoy!