Can I leave the grid now please?

This last couple of years has tested a lot of us in small business. Cafes and restaurants have had to pivot into whole new areas as a result of various mandated restrictions imposed from on high. Some have emerged relatively unscathed, while others have had to call it a day. Businesses which rely on the free movement of people also suffered. Tourism and teaching businesses like mine were just two of the casualties.

I was unable to run workshops for the better part of 2 years due to the ongoing threat of lockdowns and various border closures. I know of many local operators who have relied on steady flows of tourists to build their businesses, who have had to either hibernate or move on. Some are emerging from this hibernation now, still viable, but without a whole lot to show for a couple of years of unplanned disruption.

I’m not going to debate whether any of this was necessary, or whether it was an effective approach to dealing with the flu. Economic reality is my focus here. When small business suffers, the long term consequences are felt by everyone, especially in a small community.

And dire economic consequences are the legacy of a couple of years of all this. Now, however, we have a whole new raft of issues to deal with, and these are potentially bigger than the ones we have had throughout this extended flu season.

I’m talking about energy and fuel prices. As of last week, electricity prices for the past quarter from my supplier have gone up by 25%. Fuel prices have increased by between 30 and 50 percent. In other countries, energy price hikes have been even more dramatic, and I’m told that here in Australia we will be facing more price hikes over the coming months. We have already seen massive increases in the price of gas over an extended period, as the previous government thought it would be a great idea to sell off all of our plentiful gas supplies to the highest bidder, and save none for domestic consumption.

If you are a bakery, you might have thought you’d survived the whole pandemic intact, but if your energy and fuel costs have gone through the roof, it’s only a matter of time before the bills start scaring you out of any kind of post pandemic slumber.

Bakeries are without a doubt one of the most energy intensive businesses - the simple fact is that we heat up ovens on a daily basis to bake bread, and this heat is proving to be very expensive to make. We also require energy for refrigeration, and in many cases fuel for transporting our wares. We also are paying extra for flour, as it has to be carried long distances and is affected by these increased fuel costs.

Meanwhile, energy and fuel companies are making record profits. These price increases are not the result of a supply issue, they are to do with our international market systems. A market will very quickly capitalise on disruption, if for no other reason than to preserve or improve the bottom line or market share. We are seeing the very worst of the monopoly focused capital system play out, and many of us will hit the wall as a result - especially those who are ill prepared for these changes.

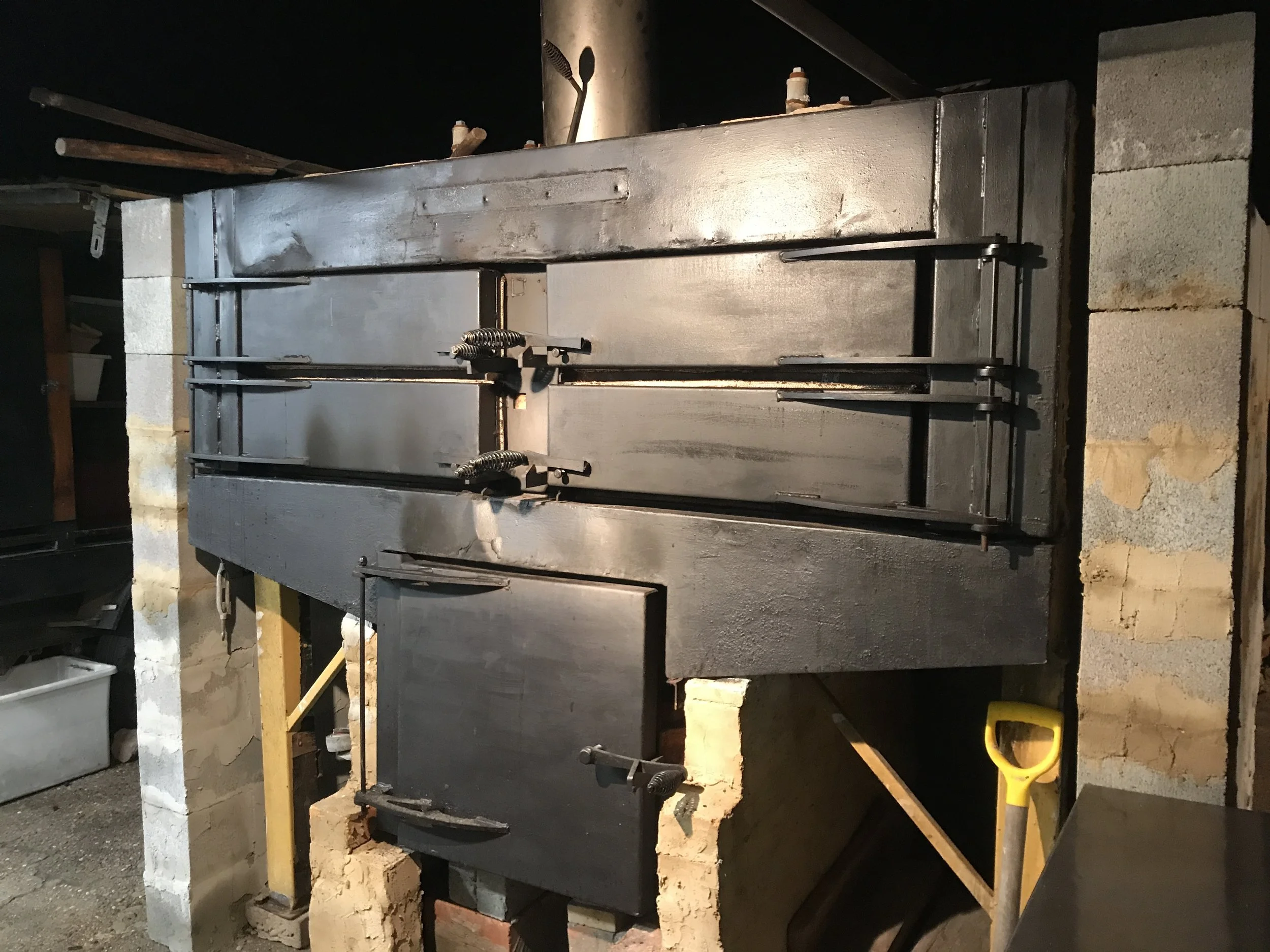

Early days with Luna

I saw the future many years ago. For my bakery, energy prices jumping suddenly has not been such a dramatic issue. I’ve been heating my oven with waste fuel (timber) for the past 12 years. In my case, my oven can run on sawmill offcut, tree fall or even old pallets. I run my oven a certain amount of the time using biochar, created from waste bread also. This past few years I’ve dived deep into the process of making ovens as well as using them, and so I’ve had the opportunity to experiment with ways of making them run more cleanly, and to get the most out of the wood. The latest prototype from my micro setup has incorporated a naturally aspirated gasification system into the firebox design, which, when running hot, emits virtually no smoke at all. The smoke actually gets burned, creating more and cleaner heat.

On a larger scale, all around the world oven manufacturers are developing cleaner and less expensive ways to heat ovens. In Europe, many old diesel powered ovens have been converted to run on wood pellets, which themselves come from waste material. However, for the average baker in Australia, the capital cost of converting from electric or gas ovens to this biomass technology is beyond their reach.

Old style shopping centre bakeries, operated by a franchisee or family, will need to find ways to pass on these cost increases, and hopefully they can convince their customers that the price of a loaf of bread will have to go up on a fairly regular basis until all this volatility settles down. I’m not sure that all of them will be able to do this, and I anticipate many will go under.

I’ve been helping new bakers to set themselves up as ‘off the grid’ as possible for many years now. All of these bakeries are holding their own at the moment - indeed, many are thriving in their local communities. They all report having to deal with a number of increases to input costs, and yet as a result of using wood fired ovens and the like, these bakeries will whether the energy storm better than most.

But being ‘off the grid’ can be leveraged in other ways, and the definition doesn’t need to be strictly associated with the energy grid. More and more people are seeing the cataclysmic events unfolding in front of us each year as a directive to detach from the system in as many ways as they can. I’m going to call this ‘off the grid thinking’ - in other words, how one can remove oneself from the established system. To do this, it is imperative that we create new systems, which in the end are more directly linked to their customers.

‘Off the grid thinking’ can involve new ways of providing one’s services or products which circumvent or reinvent traditional ways of selling one’s wares. For example, many bakeries once relied on being in a good location to get retail price for their bread. This was once an almost foolproof way to get your bread out there. Now, with main street rents rising every year, the price of retail space is becoming more and more out of reach for the small operator. Only corporate entities with share market support can afford the prime locations. This has led to many bakeries setting up on the edge of small population centers, and they are supplying their bread via subscription systems directly to their customers. Many others are setting up at home, opening up their ‘retail’ from their front porch, and, via the use of social media or email, promote their offerings to fit with their customers weekly routine. Still others focus on a variety of weekend markets to sell their wares. All of these strategies are examples of different ways of doing things, and for many they are proving to be viable and satisfying.

Tiff, from Bread Local in Esperance, has her shop in her front yard every Friday!

There are bakeries who specialise in using their own produce as ingredients in their baked goods too. I know of a farm based bakery who use almost all their eggs and some of their vegetable production in their products. I have a number of clients who mill their own flour to create their bread. I have helped cafe owners to modify their setup in order to bake in house, thereby reducing their input cost. I even have one client who grows their own wheat, mills it and uses the flour in their bread!

To my mind, these are all ‘off the grid’ ways of doing things. These different approaches to the age old craft of baking for one’s community are showing that resilience is the name of the game, and a bit of imagination and some decent research can really make the difference between making it work and giving up because things are out of your control.

I’ve focused on the commercial side of things in this article, as these energy price hikes are effecting us small business operators in very direct ways. However, plenty of home bakers are doing the same thing, and indeed, there is becoming a large overlap between home and professional baker.

I run regular 2, 3 and 4 day intensive workshops for anyone who wants to get serious about their baking business and lifestyle. Don’t hesitate to give me a call or email me on the address at the bottom of this page. Or you can check out just what’s on offer on the link below.

If you’d like to chat about the next step, why not ring me on 0409 480 750? I’ll be able to make some suggestions as to what I think might help you in taking the next step. I’m also very happy to provide mentorship on your individual bakery journey.

Keep on keeping on

The end of the School of Sourdough?

The ‘pandemic’ - or how to destroy a small business in just a few easy steps…

Whether it was a global flu, or something more to do with controlling the masses for a couple of years in a very overt manner, lockdowns and travel restrictions meant that for over a year and a half, my primary business, teaching and consulting, had to be paused. I tried to ‘pivot’ things, but in the end the business I created is all about bringing people together to learn and experience something. People were not allowed to travel, so I had no customers.

Towards the eighteen month mark, I began to think it would never recover. Every time some glimmer of hope would be presented, just as quickly, it would be snatched away again. Lockdowns, travel restrictions, changing requirements for businesses all the time - I don’t know how many times people had to cancel attending a workshop at the last minute. I had to cancel workshops many times, as it was just too hard to even attempt to coordinate a bunch of people to come together for a day to learn how to make a loaf of bread.

So my teaching business was on the rocks. Those who follow my story know that I also consult to the trade. Businesses I had been consulting for were put into a kind of intermittent hibernation as well, with many of them unable to open consistently as rules changed every week. Paying me to consult was an expense many of them simply couldn’t carry, so not much work was happening for me to help pay the bills during the extended lockdown period.

And how effective was the lockdown, mask up, coercive vaccination strategy? Here in Australia, we still seem to have high rates of the disease, despite taking all the draconian measures. And pretty soon we will begin to see many issues emerge from shutting down a fair percentage of the workforce for the better part of 2 years. Expect inflation, business closures and higher underemployment to be the result.

Musical Bakeries

While I used the time to build a new oven, the bills could not be paid without work coming in, so I fell behind with the rent. My very patient landlady decided to cut her losses and sell the property I was living and working on (for a tidy profit). When the sale finally went through, I was given a couple of weeks to move everything, and at the time there were no options for relocation of the business. Gloucester, like many rural towns, was filled with people escaping the city, so space was hard to find. So all my gear moved into storage. I lived in the local showground in my caravan for a couple of months.

I had to move twice in a space of 3 months. No teaching was possible, and consultation via zoom was all I could manage to help pay the bills. Needless to say, it has been a struggle to keep on keeping on.

As the lockdowns wore on, my business of some 30 years was reduced to almost nothing. I would be homeless now if it were not for the kindness of some local people and some friends of the business, and for that I will remain grateful. The strength of community is not to be underestimated.

Looking back, how the powers that be thought that locking down an entire nation would solve the flu I will never know, especially as doing this was clearly going to hurt many small businesses like mine. It seemed to me (and others) that the only survivors at the end of it all would be the largest corporations, who had deep enough pockets to carry the can while the rest of us fell over. I suspect ulterior motives. For every newly minted billionaire, there are a million paupers created, and the pandemic has proven this to be true.

Now that some resumption of ‘normal’ life has occurred, we are seeing the price of everything skyrocket. Is this the cost we pay for our ‘safety’? And while we are not actually locked down right now, many people really have to think twice before embarking on a car journey, as fuel prices are going through the roof. The powers that be seem to have created a sort of ‘soft’ lock down now.

The flu is still raging, btw. And a few very big companies seem to have gotten very much bigger. The pandemic has seen the largest transfer of wealth in history.

The baker goes busking

The whole process led me to explore other options, with a complete change of direction for my life and profession being actively explored. For a time, I returned to my musical roots - before I was a baker, I was a musician. So I did a spot of busking and playing at local events. It was great fun, but keeping the wolf from the door proved to be a big ask. Too big for this fella. who has got a lifetime of baking experience, and only a small amount of making a living with strings and voice to fall back on. It kept me sane, singing and playing, but to start again in this configuration proved to be just a bit more than I could manage. Nonetheless, I called my little one man band ‘The Reinvention Engine’. I thought it fitting.

Just when everything seemed lost…

However, some new opportunities for a better site for my school and bakery emerged. With a bit of fancy footwork, I found myself in a new space with cheaper overheads. It’s in an old kitchen factory in the industrial area of Gloucester. I moved in with a bunch of other ‘makers’ back in January.

It’s turning out to be very workable, and I have just finished setting up to resume production and teaching. The return of my equipment from storage has seen me renovate all my baking gear to the best of my ability, and everything looks ship shape again after over a year of inaction. Since moving here I have relocated once again to an outside setup, as the owner didn’t like the so called ‘risk’ of having a wood fired oven near his property. This has shrunk the classroom a bit, but it’s also really great to have things all potentially relocatable and close to home. I’ve really enjoyed the new space and students love it too!

Low tech is beautiful

I’ve used the new barrel oven more than a dozen times now, and while there are some teething issues, it is basically a very good piece of equipment and should serve me well. Once again I have built a decent prototype. It will need more work to make it look pretty, and there are a few little workarounds when in use, but it’s a bloody good unit so far - probably the most promising design I’ve made in the past 15 years or so. But more on that later.

Enrolments for sourdough courses are beginning again, and this last month I’ve been readying the bakery for production once more. There have been some big changes to the way I produce. These have been mulled over for quite some time, and just last week I did a trial bake using the new set up. Having some enforced down time has led me to re imagine my idea of how to go about what I do.

The dough trough

I have incorporated hand dough making into my routine. My trusty mixer was damaged in the fire, and repairs will be done when I can afford them (soon, I hope). In the meantime, I have crafted a large scale dough making trough so I can handle 30kg - 40kg doughs completely by hand.

People say this is crazy. Why would you choose to work hard when you could just fix your mixing machine? When I started out 33 years ago, I made all the dough by hand - and there have been a number of times between now and then when, for various reasons, hand dough making became my normal process. For example, during the Tour Down Under a few years back I was traveling across Australia, teaching my craft, and all the bread I made during the trip came from hand made dough. Before that, our cafe bakery in Hunter street Newcastle was based around a hand made dough system. Going back 33 years, my first commercial bakery had no mixer in it.

More recently, I’ve been using 12kg dough boxes I constructed for the aforementioned Tour Down South. I’d been getting good results, with only some loss of efficiency. I thought that if the capacity of the box was increased, efficiency might also improve. So I designed a big dough trough for making multiple doughs in, like I have seen in overseas bakeries. Now this trough has been finished, I have just begun to use it. I can comfortably manage dough of up to about 30kg at a time, without growing new muscles.

The technique is very gentle and slow - basically it engenders a different way of working. The bread is quite lovely too, being a little moister than before. At the time of writing I am perfecting the technique of mixing large amounts by hand, and I think it will be viable to go this way longer term. I am re thinking my production process, and I like the way this is going.

Once things are generating cashflow again, I’ll fix the mixer - but I want to keep the dough trough as part of the system anyway. It’s a great way to learn about dough development, and is actually reasonably efficient when used to capacity. It is large enough to handle multiple doughs at the same time, and it has surprised me with regard to how easy it is to make dough this way. It’s very a very relaxed way of working, and nothing can break down! Not only that, but cleaning up after making dough is now very easy. Those of us who use spiral mixers will attest to the fact that these machines are a bugger to clean. Not so with a trough!

The Barrel Oven

The new oven will speed up the baking process, as it easily fits 18 or so loaves at a time, and it heats up much faster than any of my previous ovens. I did a trial production run through the oven last week and can confidently report that the oven can easily bake 20 leaves per hour over an extended period. This is almost as fast as my two point five tonne ‘Luna’ oven some years ago, and is only a quarter of the weight.

Overall, the oven has blown my expectations out of the water in a good way! There will be developments on this basic design principle in future ovens. The barrel oven employs some nifty tricks, like a gasification system (no smoke) and a new way of generating large volumes of steam, which has worked better than previous methods.

So my bakery is becoming even lower tech than it was, and I believe it is all the better for it. For years I have been taking my baking ‘off grid’ in a multitude of little ways, and this is another step in this direction.

In these times of skyrocketing energy prices and ongoing uncertainty, being able to control at least a small part of my universe is both satisfying and economical on a number of levels. The bakery now has one less appliance to break down, one less power point required. All that remains now is to work out a way to simply do refrigeration without power. I’m aware of some relatively high tech approaches to this, but I’m keen to play around with the lowest level of tech available. I’m hoping this time I don’t have to have another enforced period of inactivity to think it into existence!

The Community Supported Bakery a year on

It’s been just over a year since I began baking purely for subscribers here in the Newcastle region of NSW. Before that, I focused on local markets as my retail, but after six years of doing this, I found that in our region market operators have become very risk averse. They increasingly would cancel the market at the first hint of rain or wind. Not great for the local baker who has a day to sell their bread.

It’s my second attempt at creating a Community Supported Bakery - my first was a few years back when we set up the bakery out the back of Wesley Mission in Newcastle West. We were delivering bread every Saturday all over Newcastle, and while it worked quite well, the retail business and Cafe we built on the Wesley site took over.

I learned from our experience in supplying people directly that the subscription baking model needed a few tweaks for it to work long term. This time around, after building the model around Pick Up Points (PUPs) rather than home delivery, I believe we’ve got it close to right. I’ve approached a number of strategically located businesses, whether they are retailers or cafe operators, and offered them the opportunity to become part of our Community Supported Bakery network as Pick Up Points for our subscribers. This provides the subscriber, the PUP and the bakery with positive benefits. The bakery gets a retail location for bread. The subscriber gets a convenient place to pick up their bread, and the PUP gets added foot traffic to their shop or cafe.

The baby oven I used to bake my way across Oz became the CSB’s first baking tool.

When I began baking for subscribers again a bit over a year ago, I was using the Bush Bakery MkII for the task of baking maybe a dozen loaves every Friday night here at the farm. My proper bakery, here in the old dairy shed, wasn’t built, so I was living in my caravan, trying to keep things afloat. The Bush Bakery MkII would have to do while I was waiting. It was less than perfect, and the bread I was baking from it was also less than perfect. But I pushed on anyway. Thankfully, my customers were patient.

I was hankering to bake great bread again in Luna, my main flame. She was still in pieces out the back shed as Craig Miller was refurbishing her in his spare time. I had to play the long game if I wanted to have her baking again.

Not easy for me. I always want things finished asap so I can get on with other stuff. Everything seemed to be in permanent slomo. I was going crazy. My weekly bake in my little baking trailer kept me sane.

The dough box takes shape.

At first, I was doing the whole thing completely by hand, using my ‘dough box’, which I’d recently completed, making it out of used plywood transit boards. Transit boards are what we call the plywood boards used to rest finished and shaped dough on before baking. I had plenty which were old and needed to be replaced, so I cut them up and created my dough box from them.

I had just returned from my trip across the country in the above mentioned trailer bakery, and I’d been using standard dough tubs to mix my dough by hand for the trip. The idea was to make the dough box before I left, but I ran out of time. As soon as I got back, I set to work on it, and it was finally finished. I made it waterproof and super smooth, and began making dough in it. I found that it worked pretty well for 10kg of dough - in fact, it was surprisingly efficient.

The Community Supported Bakery (CSB)

A Community Supported Bakery can take many different forms. In some places, bakeries are set up to meet community demands - and thus are entirely funded by these communities. Bakery entrepreneurs have used crowd funding to get their dreams up and running for many years. I remember meeting a baker from Berlin who had done this some 20 years ago, simply by putting handbills on the walls of cafes to gather support from the community. In other places, customers and staff are members of a cooperative. I attempted this idea a decade ago in Newcastle and failed miserably. I have seen it working though, and while the environment for a cooperatively run bakery might not be here in Australia (with a raft of incorporation laws which make forming a coop very expensive to do, and then also expensive to run when it’s finally set up) , the idea has a lot of merit and could work in places where there aren’t such onerous laws. I’d be very interested to hear from anyone who HAS managed to get a cooperatively run bakery up and going here in Australia though!

There are lots of other ways for a bakery to be supported by the community. Turns out, communities like to have bakeries which are run by people rather than corporations.

There are CSBs which simply have a membership system, with members helping to finance the bakery’s operations each year by their membership fees. In return, members get first dibs at the bakery product, often for a discounted price. Other CSBs go for a share system, where the investors receive a dividend when the bakery becomes profitable. Still others tag on the back of established buying groups, enabling them to bake directly for buying group customers.

This incarnation of my CSB is supported by a subscription system. It’s a way of supplying customers over the long term with affordable, nutritious bread. Users of the system get discount bread by committing to a number of loaves which they can have delivered, one at a time if they like, over an endless time frame. The more loaves they commit to, the better the price per loaf. Bulk buying without the bulk, if you like.

It’s like a phone card - they just top up their credit when they need to, and receive supply whenever they want. Better prices are also available when a customer orders a number of loaves at the same time. This means that a reseller can be part of the system too. Bread can then be purchased by anyone at a standard retail price without actually having to subscribe by simply popping in to one of the resellers and buying it over the counter.

The subscription system can be tweaked to be time based, which encourages regular use. Ours isn’t done that way here, because in Newcastle, at least, people want maximum flexibility. It’s a tough market! Nonetheless, our subscriber base has steadily grown over the year, and we seem to be holding on to our customers.

Our CSB so far

So a dozen loaves, paid for in advance by members of the community, was the start of it. Now we are baking about 85 loaves each time I fire up Luna the oven. We have an ‘apprentice’ who is learning the trade from the ground up, and students regularly attend our bake day workshops so they can learn how it all fits together.

Over the coming couple of months, we’ll produce a hundred loaves per bake. At that time, I’ll consider firing Luna up a second day each week - once I’ve found someone who can distribute them more widely. Eventually she’ll get fired up more days, one day at a time. The whole idea is resource management - so when the oven’s five or six tonnes of thermal mass gets fully soaked with heat, she becomes much more efficient. I just have to find homes for all the bread!

Do you know someone who would like to distribute the bread more widely, so that we can fire up Luna more often? Leave a comment after the article and I’ll be in touch!

In the meantime, our bakery is settled into a steady rhythm. We have students visiting throughout the week to learn or revise what they have learnt. Tuesdays we make sponges for dough. Wednesdays we make the dough. Thursdays we de-gas the dough we’ve made for the first time, and prepare firewood for the bake. It’s a 72 hour process from start to finish, and it makes the bread really digestible and full flavoured.

Here on the farm there is a pretty good supply of wood, but there’s always the process of trimming the wood we have to fit Luna’s firebox. This happens on Thursdays. It’s also a good day for weeding our small garden, produce from which eventually becomes jars of pickles and pastes for our family, friends and subscribers. It’s also the day I do oven maintenance - Luna gets a deck and firebox clean, as well as a blow out to clear her flue system of all soot.

Friday is bake day, and we start by cutting and shaping all our dough, ready for the final proof. Luna is fired up in the morning, and we keep her going until baking time begins in the late afternoon and early evening. By this time Luna is steady at about 220C. When we have good fuel, it’s a matter of holding her down to temp; when it’s not good, it’s a matter of cranking the firebox along until the decks get hot enough to bake. Baking currently takes between 2 and 4 hours. Then we let the bread cool on racks, and pack it for delivery Saturday morning.

Saturday is delivery day, and I head off to our 5 Pick Up Points to deliver the bread early in the morning. Deliveries are all done by 10am. Then we rest, ready to do it again next week!

One or two Sundays each month are dedicated to teaching the general public, with 101 and 102 Workshops held. It gives people a chance to learn about proper bread as well as to have a look at what we do here.

It’s a comfortable rhythm to live with, and allows time for things like gardening, administration of our subscriber system (which takes a good few hours each week), essential maintenance of the bakery and oven, and development of the site here at the old dairy shed.

Once we start baking twice a week I can see the time becoming tighter, but there is still quite a bit of capacity time wise; the routine here somehow allows for extra stuff without too much stress.

If you would like to see how things work in our Community Supported Bakery, why not book in and learn about the process for yourself or for your group? You can bring along as many as 6 people for the one price.

The Rebirth of Luna

Luna’s been rebirthing. You’d think she would have learned!

Luna’s about 7 years old. For an oven built as a prototype, that’s getting on. She’s had a robust, quite eventful life so far. She’s lived in four locations, as well as a short stint living ‘on the road’, as the centrepiece to my first travelling bakery and classroom. She was designed to be a mobile, high volume wood fired oven. She was meant to be light, heat up quickly, and be able to bake 300 or more perfect loaves of bread in the space of a market - which would be around eight hours.

For this task, she was a complete failure. The entire mobile bakery enterprise had a number of flaws, as it turned out. I may well have covered these, and the mobile bakery, in a previous blog post; I can’t remember. Anyway, that’s not what this post is about.

That’s Luna’s bush hideaway. She’s in the box…

Luna found her place as a stationary oven. She lived on a fixed site, still on the mobile bakery trailer, at a bush hideaway in Ellalong, where she performed the weekly baking duties for local Saturday markets with incredible finesse. I knew the difference Luna made - a kind of crust that only a brick oven can give you.

She was always a bit tricky to work with - she liked to be pre heated for a good 5 hours before she would really begin to sing, for example. She had some hot spots (which became completely ‘worked around’, as one does with any old bakery oven), and she needed a major clean out and overhaul every year, or she would block up (and actually melt) in parts. I had to rebuild the firebox a couple of times, and used a crowbar to open up a pathway for flue gases when it fatigued after about 5 years use.

I learned the hard way with Luna, every time, but after each rebuild she returned to work, better than ever. She was, for many years, a ‘work in progress’. She eventually became an excellent oven, capable of baking an average of 30 average sized full sourdogh loaves an hour - provided I was on my game - and more if someone was helping me. She did her job as a test bed and we improved our Aromatic Embers ovens as a result.

When the first Bush Bakery at Ellalong came to an end, I packed Luna up in the trailer, took out her bricks, and parked her in a nearby paddock, where she lived for a few months. I towed her here to the farm, and she was parked again for a few more months. We removed her from the trailer after the Tour Down South, and a boilermaker began the task of refurbishing her, with design modifications we had now applied to some of our other ovens.

Luna was my third prototype. I was the test pilot and outside design consultant. Actually, I became the crash test dummy more often than not. The first two prototypes, both named Bertha, turned out to be absolute pigs of ovens, but pigs which were made to sing for their supper nonetheless, thanks to my need to bake decent bread.

Bertha 1 in Cafe mode. Note bricked plate warmer on top!

Luna was different. We really thought about Luna - all our mistakes taught us what NOT to do. So Luna was a decent oven from the getgo - but she developed some long term issues. That’s why I was always working on her - she took a fair bit of tweaking to make her really sing, I can tell you! So when I left her in the boilermaker’s capable hands, I gave him my wish list - or at least half of it. I knew I’d be doing the other half myself.

This time I wanted to make the flame generated from the fire really stretch, so that it could do the job of heating more cleanly, quickly and efficiently. We needed to get the bottom decks more even too. Back in the day, the area above the firebox was always the hottest part of the deck. It was so hot that I had to set loaves to one side so they didn’t burn.

The boilermaker takes Luna apart with the tynes of a tractor.

Stretching the flame in Luna’s firebox.

The top decks have always relatively slow, so we set out to improve the heat here at same time.

The boilermaker built a more sophisticated and heavy duty baffle system, based on my ideas. He made the baffle itself more angled so that flame was siphoned off better when it runs against it from the firebox. I later bricked the inside of the firebox to further enhance the ‘flamethrower effect’. He rebuilt the firebox to include more brick than before. He also incorporated a whole series of cleaning access tubes to the roof of the oven, so that the area nearest the flue could be cleaned - an issue which had reared its ugly head a couple of times in Luna’s life already.

I’m hoping the changes to the flue system will eliminate the problem of soot build up altogether. I’m fully aware that I may simply be experiencing a case of wishful thinking here. Every designer wants their latest and greatest innovation to work - we always wear rose coloured glasses, to a certain extent. Sometimes, though, it pays to take out insurance. If there was still a build up of soot, despite our new modifications, at least I can now clean it out more easily than in the past.

Luna’s cleaning tubes before they get bricked and mortared.

All this work took many months. Luna was positioned in the middle of a paddock full of farm equipment. When the boilermaker was on the farm, he’d carry Luna’s bits over to the shed on the tines of the old tractor. He’d weld and angle grind and rivet for hours on end. From time to time I’d ‘lackey’ for him - just as I did when Luna was fabricated here on the farm years ago. Only then, as I remember it, I was on crutches. That’s a whole other story. Not this time - I walk pretty well these days.

More heavy duty thermal mass is added before putting Luna back together.

As the work on Luna slowly got done, a bit here and a bit there, the dairy shed also got finished - in much the same manner. A few weeks ago we carried Luna’s 2 finished pieces over to the dairy shed on the tractor, and we put her back together for the first time in a year. Then we positioned her outside the new school classroom and bakery, where she will live for quite a while, I hope.

Luna 2 showing inner layer of brickwork. This will be wrapped with besser brick.

I’ve been bricking her up, inside and out, for the past two weeks or so. It’s slow, heavy work, as a great deal of the brick is in really hard to get at places - inside baking chambers, for example. These baking chambers are only 16 cm high and a metre deep. One slides the bricks in on the end of a metal peel, and manipulates them as best as one can from a metre away. Around the baking chambers there are two layers of brick, and another layer on the top of them. Getting the bricks in place involves climbing up a ladder with brick or bricks in hand, keeping a fresh mortar on the go all the while, for maybe a couple of hundred climbs. Each brick weighs between 2 and 5 kg, and so far I’ve put roughly 500 bricks in and through and around the oven, as well as another couple of hundred inside the baffles, which we did before she was put back together. I’ve only done enough, at the time of writing this, to fire the oven up and make it work.

First layer of brickwork done. The oven is functional here, though nowhere near thermally efficient.

All this extra thermal mass and insulation will become necessary when Luna goes into production mode for the ‘Steady State Bakery’. It will operate as a heat sink, as well as a kind of heat mirror; the thick walls of brick should hold heat for days. Luna will become a super efficient oven.

i was inspired in my design for Luna by spending time at Harcourt Historic Bakery with Jodi and Dave when I did the Tour Down South last year. Their oven is capable of holding high temperatures for days after firing, as it has some 72 tonnes of brick around it. It’s an incredible piece of kit for a 100 year old oven. Dave manages to keep it hot with very little timber each day.

My version only will have maybe four or five tonnes of brick when it’s finished. The principle is similar to the oven in Harcourt though - get the brick hot, and then once it’s hot, keep it there for as long as possible. I’ll be looking for new bakery customers very soon, that’s for sure!

Next layer done. Still have to complete the outer wrapping, add more mass to the roof, and fill the besser bricks with rubble and sand.

Upon firing her up after putting her in place here, I saw that Luna was really a serious piece of flame art now. The firebox works a treat, blasting flame a good few feet each side, in sheets, spread out right under the two baking decks. It takes the oven from cold to baking temperature in just 3 hours, but will do it substantially quicker when it is fired each day or two, as it will retain a lot of heat.

Just a teensie fire here. When I fully blaze the fire, it’s too hot for my camera!

At the time of writing I’m about two thirds of the way through the brickwork. There is an ‘inner outer’ layer of brick around the baking chamber, and another around the firebox. There are two layers on top, with two more layers of grog based on mortar and recycled crushed concrete. There will be another layer of brick and mortar on top as well. There is a layer of besser brick surrounding the three sides, and I’m currently filling these with rubble, glass and sand to add thermal mass, as well as to use up everything I can from a demolished brick wall I was given. I’m going to fill a void between the inner and outer layers with insulation board.

My experience so far has been a bit different to what the world of oven builders has been telling me. One commonly held belief is that insulation like ceramic blanket or rockwool or ceramic board will ‘reflect’ heat back into the structure. While this is possible, there needs to be an outer layer of brick or thick mortar wrapping up the blanket in addition to the blanket itself for any reflection effect to occur. The blanket will eventually dissipate its stored heat in both directions - back in and out. If you wrap your blanket in brick on both sides, the blanket still fills with heat, but it slowly dissipates the stored heat back into thermal mass surrounding it. If you don’t wrap your insular material in thermal mass, you will ultimately allow 50% of the stored heat run out into the atmosphere. In addition, your insular material will actually be absorbing heat from the bricks next to it, contributing to a slower heat up of the oven itself. I learned this with Bertha 2, which took over 18 hours to heat from cold, and really only started to get useful after the second bake for the week. Needless to say, once I figured out our insulation mistake, I got to pull her apart and replace the insulation with brick, and this sped her heating time up by many hours.

The advantage of brick is that while it absorbs heat, it also reflects heat. If you sit beside a brick wall in the sun, you will experience how brick reflects heat. When it becomes ‘soaked’ with heat, it then becomes a heat source - it actually ‘radiates’. So you get reflection, absorption and dissipation (radiation) of heat, in that order. Brick, as a material to work with storing heat, becomes more efficient over time.

One uses ones loaf to make a decent loaf. Or so they say…

So far I’ve used the oven for my standard bakes, and have kept the oven warm over multiple days doing various tasks - slow roasting on one day and baking pizza on another. Luna can hold baking temperature without fire for a couple of hours at the moment. In fact, the top decks increase in temperature for the first six hours of firing, and continue to increase without fire for the next three hours. On some nights I have finished the bake and checked the baking chambers about 10 hours later, and they still held over 120 C. I think I can improve on this by a significant amount by just beefing up the thermal mass and adding strategic insulation in some places.

I’ve done the big stuff, now I will do the little things. Watch this space.

If you would like to experience Luna first hand, I run workshops for the general public each month. Professional baking workshops are held four times a year. Check out what’s on offer.

Post script:

Just a little update regarding Luna’s thermal performance. Since writing this article, I’ve filled in all the besser bricks with rubble, bits of brick and crusher dust. I’ve also enclosed a sleeve of air surrounding the baking chambers with brick. I’ve bagged the outer shell with mortar, and I’m half way through adding a layer of bottles covered in mortar over the top. Once this is done, I’ll paint the top section in black bituminous paint. At this point, the oven holds an average 100 degrees C some 12 hours after a full bake of about 80 or so loaves. It takes just a bit less than 3 hours to reach baking temperature from cold, though if I really want the oven to be fully ‘soaked’, I’ll pre heat for about 5 hours. I’m yet to gather data on how long the oven takes to heat from 100 degrees, but I think it should re heat in just a couple of hours. All the little bits I’ve done to make it hold heat longer are making a difference; and I can see I’ll be doing more as the need to use the oven more often grows with demand for bread. I’m also noticing that to heat the oven takes less fuel now. This is a bit unscientific, because I’m using different wood from around the farm, but the effect is still noticeable. I still don’t have enough demand to fill 2 days baking, but this will gradually build as I get out and gather more subscribers.

The reinvention of the Bush Bakery

The workshop

Nothing excites me more than a new project. I've been holed up here about 15 minutes out of Dungog, at my mate Craig Miller's Mum's farm; I've set up my work space in the old dairy shed. My base resource is what used to be my markets shop trailer.

Your Challenge, should you choose to accept it...

For this project, I've set myself some really tricky challenges - not the least of which is to build the Bush Bakery Mk II almost entirely from existing materials - a kind of re purposing/recycling process. Essentially, I'm stripping out the inside of what was the shop trailer, and then turning it into a mobile baking classroom-cum-sleeping quarters for the Tour Down South.

I gotta say, I'm learning so much about recycling building materials, and how to work in this manner. It's about the third or fourth carpentry project I've done this way, and I feel as though I'm finally getting the hang of it. I've been working on it day and night for the past week in order to test it out before hitting the road properly in June. So far, I have spent a grand total of $100 on the refit; everything that came out of the old shop trailer has been broken down and reused in the new classroom trailer. My carefully laid out pile of timber, hardware, assorted building materials and baking equipment which came from both this trailer and my old classroom at Ellalong has been utilised well. Indeed, towards the deadline (Friday for Saturday's workshop) I was actually starting to run out of materials. Luckily, I managed to improvise well enough to get the new trailer ready for a trial run.

I took the newly repurposed Bush Bakery Mk II out yesterday for the first time to conduct an outdoor 101 class yesterday. I have been in a state of high anxienty all week, as I've been working on the trailer. There is nothing worse than equipment failure in the middle of a workshop, and so many things can go wrong when you are making bread from scratch with very little actual bakery equipment. Thankfully, everything worked quite well, and my students seemed pretty happy with the bread we baked, as well as the day in general. This feedback nourishes me and allows me to keep going on the project, knowing I'm on the right track.

One of the highlights of the day was just how good the oven I'm using works. This oven was made in 1924 in Massachusetts, USA. It weighs virtually nothing - maybe 5kg - and it can bake a few loaves at once. It was the inspiration for the Bush Oven which Craig and I are currently designing for the Tour, and yesterday was the first time I have actually used this beautiful antique oven. Wow! What a clever little thing it is. I've been reflecting once again on how we think we are currently really technologically savvy, and yet back in 1924 they made a super efficient oven which can do a lot of baking from not much at all. We fired the oven up with lightweight firewood, and managed to bake a baker's dozen worth of loaves in a just a few hours. The oven spring we were getting was nothing short of amazing. Crust colour wasn't great, but the crust itself was brilliant. Leathery, crisp and thin. Colour can be addressed in other ways - but black ovens like this one are notoriously difficult to put steam into. Nonetheless, Craig and I are now working with this idea for our new Bush Oven. Stay tuned for progress here.

The trailer currently is barely functional. I got the basics done for the workbench, but I had to improvise a way to hold wooden transit boards for final proofing which was barely adequate. The idea I am working towards is a kind of third world retarder/proofer, based around the same technology utilised in the Coolgardie Safes of last century - essentially coolers which worked by evaporating water. My version will have walls made of expanded clay pellets, which were used in an aquaculture setup here on the farm, and which will be wrapped in wire mesh. These pellets hold a lot of water, and the way I'm going to build it will allow air to pass around the pellets, causing evaporation as well as turbulation. Airflow will be provided by vents which are on the front of the trailer, so when I'm moving the Coolgardie will cool things down. When I'm stationary, the cooler can convert to a proofer by wrapping it up in calico and placing a water bath warmed by hot coals from the oven. If I build it right, it will seal well, and in theory will satisfy my hard core off grid requirements.

Plumbing for the Bush Bakery will be very simple. There will be hot and cold water, as you would expect; I've salvaged a stainless steel water tank from the Bush Bakery Mk I, and this will sit on the roof and be heated by the sun. I've used this incredibly basic technology before, and it heats water well, even on cool days. The tank will connect with a tap inside the trailer, and will also provide the water for the Coolgardie unit via a trickle feed system. This will have a valve fitted to regulate the water flow so that the cooler will have the right amount of water for evaporation. Cold water will simply come from a hose connection. Weight is an issue with this small trailer, so I won't be carrying much water when on the road.

I've written about the mixing tools here already - I'll be making a Baker's trough for this purpose. More about this when I've made it. Again, I'll be playing around with my version with a view to optimise it for weight, volume and mechanical advantage. By the time it's ready, I'll have most of the rest of the trailer's infrastructure complete, so there will be some trials to do before I roll on down the road with the Bush Bakery Mk II.

For the sleeping quarters, I'm going to have a simple fold out bed on the opposite side of the trailer to the kitchen. I've insulated the roof, and will be insulating the wings which fold out to provide shelter. I'm still deciding how to create walls and windows for my fold out bed - I'm tossing up between some sort of canvas/shade cloth roll down wall system, or something a bit more sophisticated made of wood. It will be the middle of winter, so it is going to have to be able to keep me and my dog Pippa warm and dry every night. Pippa's bedroom will be on the ground under the fold down bed. I'll be adding a mesh section under it to keep her contained while the moon is out.

I've got six weeks to finish and test my Bush Bakery Mk II. As usual, I am confident I will have it all good to go by then - but anyone who saw me a few nights ago before Saturday's workshop would know, sometimes I tend to be a bit more ambitious with my projects and the deadlines I set for them than is humanly possible. That's just the way it is. I can only plug away, and hope that I get a good run with things. Sometimes jobs like this can go smoothly and without too many hitches. Other times, stuff just eats up time, and progress is slow. This is a real risk with a project of this type - particularly when one is working with 'inventions' which one hasn't ever done before. There are many unknowns. In addition, my choice of re using and recycling as much as possible means I have to make do largely with what I've got. This is not simply an idealogical position - here at Wallarobba, it's a forty five minute drive to the nearest large hardware store, so you really can't just nip down and grab things on the spur of the moment. Buying hardware in this case involves planning, lists, and a flexible brain. Luckily, when we dismantled the Bush Bakery Mk I, materials were sorted and carefully dismantled because I knew they would be used again. Thus, my supplies are already waiting for me to use them - though I have no idea what things I will actually need as yet!

I do love a challenge. Keep an eye out for future posts right here to see how it's all going. If you would like to book for a Bush Baking Workshop, and see and use the new setup, you can book for any of the workshops here. Keep an eye out for new venues via our facebook page as well. I'm coming your way soon!

Times of change - the baker hits the road.

Taking Luna's Vital Signs as I prepare for a baking session at a 101 Workshop.

I've been working and teaching at the Bush Bakery for the past few years now. It's been an absolute revelation on so many levels. From thirty years of running numerous bakeries, lots of common issues emerge; big ones include energy usage, wastage, working civilised and family friendly hours, and the effects of long term baking on the body. Others have been how can one simplify the production of sourdough bread so that it is consistent; how to work with the seasons; how to create the most nutritious bread possible sustainably and ethically. There are more issues on this list as well, though the article will rapidly step beyond the subject of the title.

Anyway, I've had to assess them all, and re assess them, over time. The Bush Bakery, then, has been a test bed for the resolution of many aspects of being a baker, and about the practicalities of life in the baking trade. And I have to say it has been a total success as a means of coming to grips with many of these issues. As a bonus, I've also been able to bake some of the best bread I've ever made there, and have taught hundreds of you the basics of the baker's craft since being here.

Baking in the Elements

My past three bakery incarnations have involved semi outdoor baking; it seems to be a natural extension to the idea of working a wood fired oven. There are numerous benefits with this style of baking. The obvious one is avoiding baking the actual baker, which can occur by enclosing the baker in a box with a couple of tonnes of hot thermal mass standing right beside them. Every summer, bakers everywhere adapt to large volumes of sweat being emitted from their pores as they attempt to keep an oven filled with melting dough. It's never pretty.

I've always considered a baker's summer as an opportunity to clear out the sweat glands and lose a bit of weight. You sweat a lot, but you just embrace it. You learn to hydrate at levels only athletes can appreciate. Being close to the breeze really helps, though. The Bush Bakery has two open sides, and all I need is a decent fan to move the air around; thus, surviving in hot weather is achievable.

On the other hand, winter here is delicious, with a couple of tonnes of hot brick on bake day to remove temperature fluctuations. It presents its own issues, of course; not the least of which is to attempt to get the bake done in a reasonable amount of time while the weather is cold. Things slow down in the baking world more and more as the mercury gradually disappears inside its little glass tube.

When you are semi outdoors, the cold is pretty influential. Granted, it doesn't get all that cold here in the lower Hunter Valley; though it's still cold enough for you to really know you are in the middle of winter. On a baking week, I work three days preparing dough, and I don't fire up the oven at all. My environment can be pretty harsh in the dead of winter, with the cold, the wind, and the work all being relatively relentless. In addition, my techniques involve cooling down dough, so much of the time my extremities (fingers and hands) are being reduced to the temperature of the dough I am working, and it's usually somewhere below ten degrees C when it emerges from the fridge.

Baking strategies have to be devised which are almost diametrically opposed to those used in Summer.

(Having baked for about thirteen winters in the Blue Mountains, the climate in the Lower Hunter Valley is a walk in the park by comparison. Up in those hills, it tends towards 'brass monkey weather' for the majority of every year; winter baking presents even more intense challenges.)

Overall, though, a cooler climate is better for slowly fermenting sourdough than a hot one. Bakers are nothing if not adaptive creatures, I hasten to add. Once you have survived half a dozen seasons in the same environment, you will learn how to cope with it, no matter what. Nonetheless, practitioners of my craft have always been acutely aware of the seasons; the elemental forces dictate the strategy the baker plans for each bake. In this regard, bakers share a great deal with farmers, who are always learning to work with the elements.

A Zero Waste Approach

The Bush Bakery is about more than baking outdoors. I've written on other forums about some of the other things I've been trying to come to grips with while I've been working here. Things like waste. The Bush Bakery is as close to a 'zero waste' bakery as I think it is possible to be. It is largely a closed loop system. On the input side, there are various forms of plastic packaging and so forth which are quite difficult to avoid in the first place, but pretty much every input and output have been thought about in the larger scheme of things. Everything has multiple uses on the way to its end point. I re-use semolina, for example, three times; first, it is sifted over and under the dough; then, overs are sifted and returned to the container for next use, with any 'scarf', or moistened semolina sifted out and put in the ash bin. Finally, when the floor of the oven is swept clean after loading and emptying, the burnt semolina leftover is also put in the ash tin. This burnt semolina is used at the end of each firing cycle as fuel. It provides a quick burst of flame, and so is useful at various times of the bake when the firebox needs a kick along.

Waste from re stocking days and workshops is sorted through into incenerables, recyclables and compost. My flour bags get used to establish the fire on bake days, as they are made of paper. I have also used them for various gardening applications as well. I've gradually refined the process of bringing unsold bread from my markets based retail operation into the production process as fuel. Thus, I have been able to refine my way of making 'organic coal', or biochar, using waste heat from the oven. This biochar is now an essential fuel to power the oven.

We discovered 'organic coal' by accident about seven years ago, with one of the first prototype woodfired ovens we made, Bertha. A tired baker would sometimes leave a loaf up the back of the oven without noticing. The following morning when the decks were swept clean for the day’s bake, a black, lightweight piece of coal was discovered. It was thrown in the firebox to dispose of. Wow! It burned like a bomb!

Organic coal has been fully incorporated into my baking practice now.

I also power the oven with sawmill offcuts, making the whole energy supply issue very easy and very cheap to resolve. By driving my oven entirely with waste, I estimate that my total baking setup costs a quarter of conventional commercial baking systems to operate, even when you take into account the extra time you need to devote to maintaining these energy sources.

Flour dust gets up your nose (and later, everywhere else)

Long term bakers often tell me that flour dust is an issue for them. Some of them, when they combine it with other irritants like tobacco smoke and the like, end up with greatly reduced lung capacity, and even mild emphasema. Flour build up in the lungs is known as ‘white lung’. I didn’t think it was an issue for me. I haven't smoked in many, many years; but at Ellalong, with the bakery down the hill and the dough room up the hill, I was experiencing shortness of breath. I just put it down to my age, and that bloody big hill. By chance, I decided to move the dough room down to the Bush Bakery to make more space in the house. The Bush Bakery had open walls, lined with shade cloth. Suddenly, this shortness of breath decreased quite dramatically. I guess my lungs were filling up with flour from making dough in an enclosed space. In future bakeries, I intend to design a more sophisticated version of this indoor/ outdoor setup.

Change as a constant

Fundamentally, I think I love the elements. This 'hot and cold' thing is good for me. My soul isn't attuned to sameness, and I need change to keep it happy. The seasons provide this, particularly when one bakes outside. This constant change, I think, is also the reason I have continued to bake for the past thirty years.

Any one who knows me will attest to the fact that I am deeply attuned to total reinvention from time to time, and that I do it on a fairly regular basis.

For me to have been able to sustain myself as a baker for such a long period is testament to the fact that natural baking, in the elements, offers change, a kind of daily process of problem solving; in short, baking has a mental attraction that simply can't be replicated any other way that I know of.

Which brings me to the subject of the title.

I've been talking to people all around Australia over the past few years; plenty of you can't get to the Hunter Valley for a day or two, but you really want to learn sourdough in a hands on way. You know about what I do, and really just want to learn the basics of the craft, first hand, from someone who isn't full of hot air and limited experience. Many of you have indicated that you are inspired not only by my methods, but also by my methodology; ways I am learning to remove waste from the baking business, simple and cheap ways to get 'off the grid' on every level; techniques to help people consider ALL the breadmaking inputs and outputs, and to make environmentally sensible decisions around each baking practice; and mostly just to bring baking proper bread back to the people.

It appears my ideology, my experiments, my successes and my failures over many years have all struck a chord; especially of late. The planets are aligning in all these endeavours. People want to investigate low tech solutions to all manner of enterprises. People want to build local networks and utilise what they have. They want to reduce food miles, make stuff from scratch at home, or to know the person who made it. They are fascinated by what can be done with 'third world' technologies, with collaboration, with an 'artisan' mindset.

People are needing to knead! The artisan baking community have been reinventing bread, one workshop, one loaf at a time, for many years now. I began my personal and professional journey almost three decades ago, and the recent embrace by 'the people' has been very encouraging.

Many of you have come to a 101 workshop and have ended up owning a bakery! (You know who you are, and I do wish all of you well!)

Hitting the road Punning

I have been encouraged by you to take the next step. Most of you just want me to keep baking for you here in the Hunter Valley every week, and while it's been very difficult to 'peel' me away from the baking lifestyle, I gotta say the baker needs a ‘rest’ from ‘kneading’ to make his bread. He wants to make his dough while on the go. While I know where my bread is buttered, it's your bread I'm interested in. Specifically, how it's made, and where!

I want to come to your town and show off some tricks I've learned this last thirty years or so. I want to speak, to share my lifetime's passion directly with you. I want to come to where ever you are, and to show you the tricks of the trade, first hand. And I want to hear all about your place, your town, your region while I'm there. I definitely want to meet you.

I've been looking into ways of baking that are so simple, so basic, that absolutely no electricity is required. I'm creating a mobile, totally off the grid baking classroom, which can be brought to your town, your suburb, your area, your market, and which can practically demonstrate the baker's craft with minimal fuss.

I can do demonstration workshops at your event. I can run half day, semi 'hands on' workshops where people get to bake some bread to take home. I can also run full day and multi day baking workshops where you get to make the dough completely from scratch and then bake it. With the trailer I'll be bringing, I can do this pretty much anywhere. I’m going to build a mobile, Bush Bakery MkII. It will be for teaching how to bake.

So, these workshops will be focused on Bush Baking, using techniques not dissimilar to Australia's original bakers. Minimal, low tech refrigeration, no electricity, no running water. Just beautiful, hand made woodfired sourdough bread. Baked in the elements, come what may. It's seat of the pants baking at it's finest, and I want you to come and be part of it, wherever you may be. There will be triumphs and there most certainly will be failures. But no matter, I guarantee you and I will both learn lot every time, and that neither of us will ever forget it!

The route so far:

I'm heading South from the Lower Hunter Valley of NSW in June this year. The plan is to head (initially) along the coast, with possible stops in Sydney, Wollongong, and Berry; then inland to Canberra, and the Bendigo area; then on to Melbourne, Adelaide, maybe a stop around Ceduna, then across the Nullabor to Esperance, Albany, Margaret River, Perth, Kalgoorlie; and than back again with some diversions along the way. The idea is to run Bush Baking workshops for small, medium and large groups of people wherever I can. I want to tag into events which may suit this teaching format, and I want to use local knowledge along the way to really connect with each region. Things like local shows, field days and markets. If the idea works, I'll do a similar one next year, only this next time I'll head north. It's a big country!

It would be great to hear from people in some of these places between now and then. If you would like me to teach your group, or in your town, or at your event, I'll be on the road from June to September this year. There is still quite a bit of flexibility in the time and exact route of my journey, so if you reckon I really should hook into something you have planned, then talk to me! I'm all ears! In coming weeks I will be busily tieing down dates and locations, so watch this space for developments. If you would like to discuss things with me my number is 0409 480 750. Please feel free to call.